What are the types of welding machines and their applications

When someone thinks about buying a welding machine, they may not even suspect how many models exist on the market. The capabilities for welding the thickness of the metal and types of alloys depend on the equipment selected. This review will show the types of welding machines by current sources and welding modes, which will facilitate the selection of goods that will best meet future challenges.

Difference of welding machines by source type

To understand what types of welding machines are, it is worth knowing that the equipment is divided into types of current sources and methods of welding performed. The voltage from the network 220 V and 6-32 A is not suitable for the welding process, so it must be converted. The following options have been developed for this.

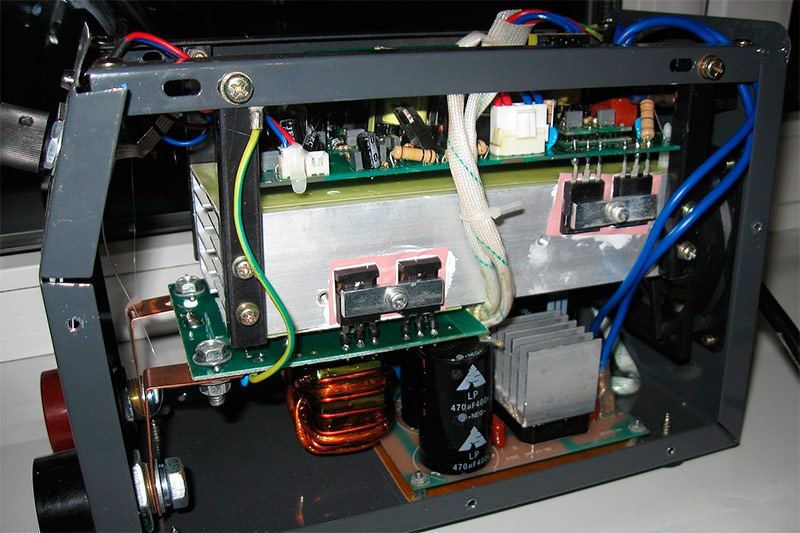

Inverters

This is equipment that consumes alternating current from a network with a frequency of 50 Hz and changes its fluctuations to 100 kHz. In addition, the voltage is rectified twice. Ultimately, welding is carried out at a direct current of 30-300 A with a voltage of 50-80 V, which contributes to smooth seams, deep penetration, less spatter of metal.

To implement the process, the inverter circuit contains:

- a step-down transformer;

- rectifying block (diode bridges);

- key board;

- transistors

- second transformer.

Two cables come from the apparatus, one of which is connected to the product, and the second to the electrode holder. The advantages of the inverter are compact dimensions relative to other sources of welding current, light weight of 3-6 kg and quiet operation (pleasant rustling of an electric arc).

Welding inverter.

Inverters themselves are divided by the type of transistors used in them.

Mosfet Inverters

Welders of this type are usually cheaper by using Mosfet inverters that are simpler in design. Transistors were developed about 50 years ago. They are reliable and well convert current for welding ferrous metals. But they weigh more than their counterparts. Even for the normal operation of the inverter, there should be about 20 such transistors in the electronic circuit (for models with 180 A). These types of welding machines have protection against overheating, which is triggered after reaching 60 degrees, so the models are characterized by low PV in 30-40%. Free layout and large parts simplify the master's access during repair.

Welding inverter with Mosfet transistors.

IGBT Inverters

This is a more modern generation of transistors, which is installed in expensive welding machines. The weight of IGBT is less than analogues and they are required up to 10 units in inverters with a capacity of 180 A. All this contributes to even smaller dimensions of welding equipment and weight reduction. Overheating of the IGBT transistors is triggered after 90 degrees, prolonging the total time of use of the device. On the one hand, in such a circuit of the welding machine there are fewer parts, but on the other hand they are very small and it is more difficult to replace something.

Inverter with IGBT transistors.

Rectifiers

Among other types of welding machines for manual welding, rectifiers stand out, characterized by relative cheapness and the ability to create high-quality welds. They consume 220 V current from the network and lower it through a transformer to 40-80 V, and increase the force to 200-400 A, depending on the power of the model. Further, the voltage passes through the diode block and is rectified. The design has elements of start-up and protection.

Welding is carried out by direct current. The equipment is reliable and durable. There are versions for domestic and industrial use. Suitable for welding ferrous and non-ferrous metals, cast iron. The main disadvantages are the large weight and large dimensions. When they are cooked, the rest of the network is drastically squandered, and other devices may not work correctly.

Welding rectifier.

Transformers

The cheapest type of welding machines are transformers. They consist of two windings: primary and secondary. Devices work on the principle of magnetic induction. The distance between the windings helps to increase or decrease the current strength. Welding is carried out on alternating voltage. The devices are suitable for joining ferrous metals. They are simple and reliable. Of the minuses of this type of equipment, high weight, strong hum, high metal spatter and large dimensions stand out.

Welding transformer.

Types of welding machines depending on the type of welding

Having considered what kind of welding machines are by type of power source, let's move on to their varieties by welding modes.

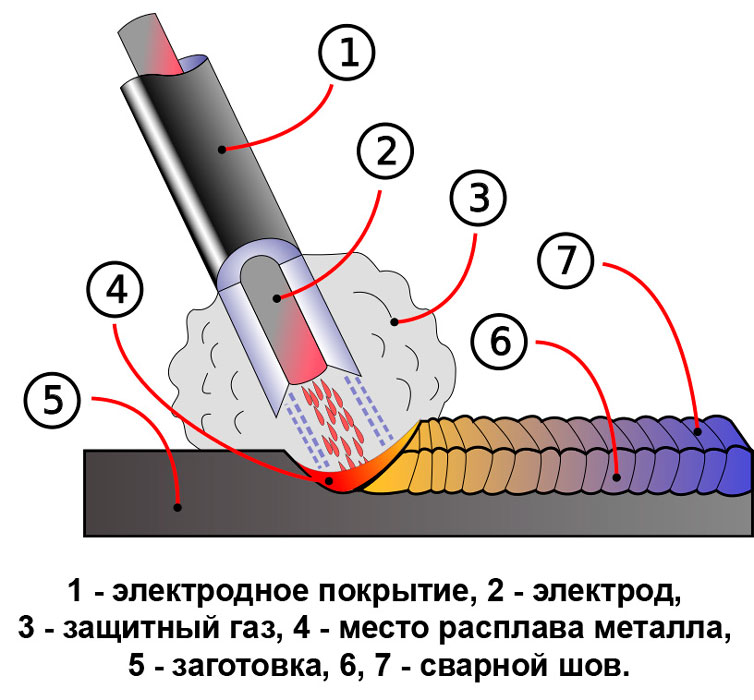

Devices for manual arc welding MMA

These types of welding machines are based on inverters, transformers or rectifiers. A welder wields a holder on which a melting electrode is fixed. A metal rod closes the arc on the product and serves as a filler material. The outer coating, when melted, creates a gas cloud to protect the weld pool from the external environment.

Manual arc welding machine - MMA.

Application. This type of welding can connect ferrous metals. If you install electrodes with a stainless rod, then you will be able to weld alloy steel. But the speed of work is slow, enough experience is needed to get a high-quality connection, you constantly have to control the length of the arc, since the electrode is reduced.

Scheme of the electric arc welding process.

Watch the video about MMA welding machines:

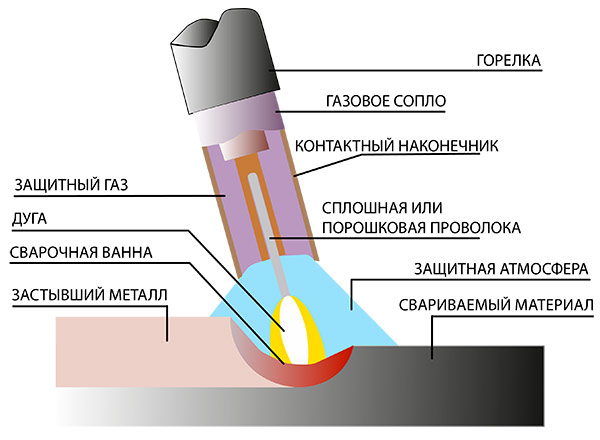

Devices for semi-automatic welding MIG / MAG

MIG / MAG welding is called semi-automatic, since the seam is carried out using a torch, but the wire inside is fed from a special mechanism from the coil. The principle of operation is similar to MMA, only a compact burner is provided instead of the holder. The metal is connected by an electric arc (the mass cable is connected to the product, and the “plus” remains on the wire).

The device for semi-automatic welding - MIG / MAG.

Application.Thanks to the continuous filing of the additive, you can create long, neat seams. There is no slag in the weld pool, so it is better for the welder to control it. Protection from the environment is the gas supplied from the cylinder through the nozzle of the burner. This type of welding is quick and allows you to connect metal with a thickness of 0.6 to 20.0 mm. Depending on the type of wire being installed, it is possible to weld ferrous metal, stainless steel, aluminum. But it is required to carry a cylinder. Even with wind and outdoor work, the weld pool becomes defenseless (the supplied gas is blown off).

Scheme of the process of semi-automatic welding.

Watch the video about MIG / MAG semi-automatic welding machines:

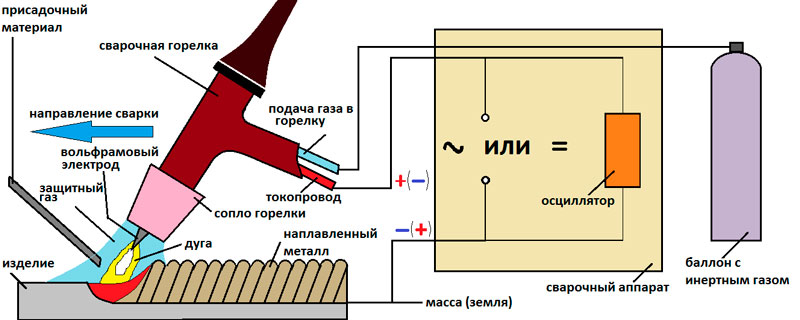

TIG Argon Arc Welding Machines

TIG welding is performed by inverters. There is also an electric arc, but it burns between the product and a non-consumable tungsten electrode. The latter happens in diameter 1.6-3.2 mm and is ground in the form of a sharp cone. This allows you to create narrow seams. Connections can be made both at the expense of only fused edges, and with the help of an additionally supplied additive by the welder’s free hand. The weld pool is protected by argon, blown out of the nozzle of the torch.

Argon arc welding machine.

Application. When working on direct current, it is possible to weld ferrous metals and stainless steel. There are types of welding machines with AC / DC function, designed for welding aluminum. It will be possible to cook with such equipment very carefully and economically, but the speed of the method is much lower than the semiautomatic device.

Scheme of the argon arc welding process.

Watch a video about welding machines for argon arc welding:

Universal welding machines

Universal models of welding machines combine several welding modes at once.

Here are the existing options:

- MMA + MIG. The model is able to cook with coated electrodes and wire fed from the drum. In the first case, it is practical for electric welding cutting, and in the second for serial production of sheet metal parts or body repair.

- MIG + TIG. Semiautomatic device with the possibility of attaching an argon burner. Allows you to quickly stitch stainless steel and ferrous metal using the MIG mode, as well as connect aluminum, switching to TIG.

- MMA + TIG. Inverter for welding with conventional electrodes and tungsten rods. Practical for alternating welding of ferrous and non-ferrous metals where high speed is not required.

- 3 in 1. The most versatile machines capable of welding in MMA, TIG and MIG modes. To do this, on the front panel there are several sockets for connecting the corresponding burners. Such equipment is acquired for the most versatile tasks.

Spot welding machines

Spot welding machines come in the form of models with tongs for double-sided welding or with a gun and reverse hammer for single-sided welding. The first are used for the assembly of thin-sheet structures (boxes, doors, gates, gates).

Apparatus for spot welding on both sides.

The second are used for body repair, when you need to weld to a plane without access to the back side. There are hand-held portable models with a weight of up to 16 kg and stationary resistance welding machines. The thickness of the welded metal varies from 3 to 9 mm.

One-sided spot welding machine.

Plasma welding machines

These types of apparatuses use an electric arc burning in a nozzle between the cathode and the anode. Through it, compressed air is passed from the compressor, which forms the plasma. Closing the mass on the product allows you to transfer the arc and make of it not a duty, but a cutting arc. If you use filler wire, then this method is suitable for welding parts.

Apparatus for plasma welding.

Watch the video about plasmoresis:

Gas welding machine

Under the apparatus here is meant an acetylene generator that produces gas by the interaction of carbide with water. In addition, a cylinder with oxygen that supports combustion and contributes to the development of flame temperature up to 3000 degrees is connected. But recently, more often than not devices are used, but simply two cylinders (acetylene + oxygen or propane + oxygen). Then for welding it remains only to purchase a torch and two sleeves.

The flame heats the edges of the metal, and the filler wire fills the weld pool and increases the height of the seam.

Apparatus for gas welding.

Application. This method is suitable for welding pipes and tanks with wall thicknesses up to 4 mm. Gas welding does not need electricity and can be carried out in the field, but the welding speed is very low, and the probability of deformation of the product from heating is high.

Understanding the difference in the types of devices for welding according to the current source and the welding method, you can choose equipment for specific tasks, whether it is welding parts in a garage, body repair or serial production of products in a workshop.