Cable for the welding machine: brands, characteristics, how to choose

Often, the cables supplied with the welders are short and have an aluminum core that quickly overheats. In order to equip your inverter with reliable cords for the electrode holder and mass clamp, you need to figure out what brands of welding wire are, and what to look for when choosing. So, you can choose a cable for the welding machine, which will work comfortably at any air temperature, and the electric line itself can withstand the load.

Marks of welding cable and their characteristics

Since the welding cable experiences increased loads both from the side of the apparatus and from external factors (construction conditions, friction against the ground or concrete, heating, frost), its service life and effectiveness depend on the selection. First we’ll have a look at what welding cables exist and what are their differences.

KG

This is the most common type of cable, which stands for "flexible cable." It is suitable for operation with direct current up to 1000 W or with alternating current up to 600 V and frequency not exceeding 400 Hz. The wire is used to connect the inverter to a 220 or 380 V network, as well as to attach an electrode holder and a mass clamp.

KG welding cable.

KOG1

Unlike the previous cable, a thinner core diameter is used here, so the cord is especially flexible. As a result, he has a smaller turning radius. This is especially useful when welding in inaccessible places, when the welder needs to put his hand with the holder at an unusual angle. It is also practical when working at heights where it is customary to wind the cable around the arm (to make it easier to hold) - then the loops will not stick out much to the sides. Unlike KG, it is designed for 220 V pass with a frequency of 50 Hz.

KOG welding cable 1.

KGN

Such a welding cable with the addition of the letter “H” in the marking means that the material is non-combustible. The insulation shell is made of a heat-resistant coating that can withstand temperatures above 200 degrees. This wire is useful if you have to conduct electric welding / cutting literally in ignition conditions (the needs of the Ministry of Emergencies, repair crews on ships, etc.). In the domestic and industrial fields, this is practical when the assembly is large, and the welder needs to move around the areas just welded to continue work. Then the cable in contact with the heated metal will not melt.

KG-HL

The index of this product contains the letters "CL", implying permitted use in the cold. For this, a special rubber is added to the composition. It retains flexibility at temperatures up to -60 degrees, so it is especially suitable for working in the Far North. If you often have to conduct welding in the winter on the street, then pay attention to products labeled KG-HL.

KG-HL welding cable.

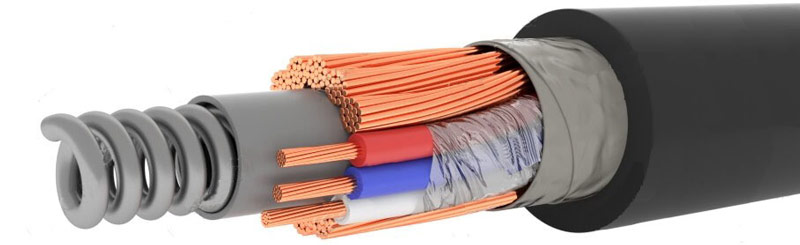

CPES

This is a type of cable where a spiral tube is used instead of a core. It is designed to pass inside the wire, to close the circuit and excite the electric arc. The wire can be either solid or tubular, with a flux inside. A cable is used for semi-automatic welding. The price of the cable depends on the inner diameter. But the hollow design contributes to a reduction in service life of up to 1.5 years. Such an electric main is capable of transmitting voltage of 42/48 V irrespective of the type of current (alternating or direct).Apply the low-voltage line at temperatures up to -10 degrees.

KPES welding cable.

Pic

A cable with the designation KVS implies the presence of polyvinyl chloride in the insulation. Such a sheath is more resistant to abrasion and is suitable in cases where the welder needs to move frequently by dragging the cable along the floor. Insulation will help keep the core from being exposed. The cable withstands a stable transmission of voltage of 127-220 V. The temperature range is -40 ... + 40 degrees. But PVC does not have such flexibility as rubber, so it is not suitable for an electric holder. Most often, PVC wire is used to connect the welding machine to an outlet.

KVS welding cable.

KGT

This type of cable withstands air temperatures up to +85 degrees, therefore it is optimal for operation in a hot environment. The coating actively resists mold and mildew, and the cable is suitable for use in humid, warm conditions.

How to choose a welding cable

Having understood the labeling of goods, we will move on to practical tips for choosing. The welding cable must match the apparatus with which it will interact. There are other parameters selected based on upcoming welding tasks.

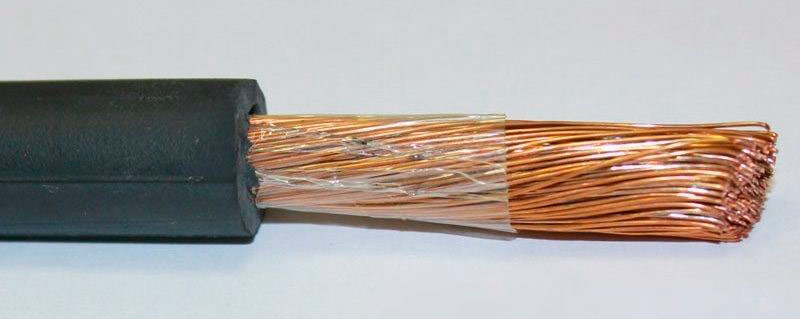

What should be the core of the welding cable

A welding cable connected from the apparatus to the holder and ground can be single-core (for example, 1x16). The first digit means that in the context of his core is a common, not divided into two or three isolated lines under a single shell. This design reduces heating and promotes accelerated voltage transfer from the source to the holder.

Single-core welding cable.

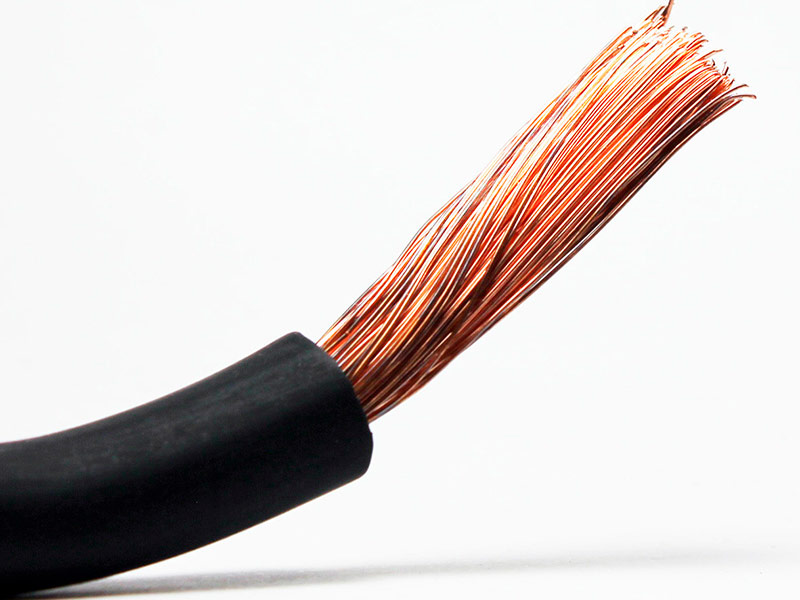

Stranded cables are designated 11x30, where the first digit indicates the presence of 11 separate cores. This design is used in industrial plants using a voltage of 500 A and above.

Stranded welding cable.

The core itself is aluminum or copper. In stores, welding machines are most often equipped with aluminum cables, since they are cheaper. This is enough for a novice welder or a rare use of an inverter.

Aluminum welding cable.

Professionals always install copper cables, since they have a resistivity of 7 times less than that of aluminum. As a result, current losses are reduced. Even copper bends better and warms less.

Copper welding cable.

Chinese cheap cable can be called copper, but contain Cu no more than 70%. This is easy to notice by the dull color of the core in the section. For domestic needs, the product is suitable, but for production it is better to abandon it.

Welding cable cross section

Inside the metal core are thin wiring, which can be from 30 to 1000. Their total cross section is selected according to the power of the device and the current used. For example, a cable with a cross-section of 1x6 mm² is designed for a maximum load of 11 kW with a current strength of 80-100 A. But you can never use the calculated values for the maximum. It is optimal to always divide them by 2. As a result, such a wire is suitable for a power source with a power consumption of 5 kW. With increasing current strength (A), it is necessary to increase the cable cross-section, otherwise it is the same as trying to refuel a car at a gas station through a straw - a narrowed passage will reduce productivity.

So that there is no loss of welding current, the cross section is selected based on the output power of the apparatus according to this table.

| Current strength, A | Cable section, mm² |

|---|---|

| 80-100 | 1x6 |

| 120-150 | 1x10 |

| 150-180 | 1x16 |

| 200-250 | 1x25 |

| 250-300 | 1x50 |

| 330-400 | 1x100 or 11x50 |

| 500-600 | 1x120, 11x95 |

| 600 | 1x185 and above |

If you cook with a "tweak" at a current of 80 A, then you can completely do with a thin cable 1x6 mm². But this will not allow the use of an electrode "three". Therefore, the apparatus must be equipped based on the maximum possible welding current. For a household inverter in the country, a minimum indicator of 1x16 mm² is sufficient. The workshop requires 1.25 or 1x50 mm². Work with a cable with a smaller cross section leads to its overheating and melting.

Cable Flexibility Requirements

For welding, a cable with a flexibility of at least grade 4 is required.More rigid wires will twist the hands of the welder, it is more difficult to wind them up for transportation, it is inconvenient to manipulate the holder when leading the seam in the ceiling or vertical position.

The cord with the designation KG belongs to the 5th class of flexibility. His diameter of the "hair" is 0.41 mm. Products marked with KOG belong to the 6th class. Increased flexibility is achieved due to the diameter of the "hair" 0.21 mm.

Cable insulation

The cable sheath is made according to GOST 23286-78. Insulation should not be thinner than 1.1-1.2 mm in order to reliably protect the live part from exposure. The outer winding is made of rubber with the addition of various components. It should be soft and flexible to the touch. The insulation class is indicated by letters and indicates the maximum heating temperature that the shell can withstand.

For example: the index F means 150 degrees, and H - 180.

The length of the welding cable and whether it can be increased

The length of the welding cable affects the ease of movement of the welder when work is carried out along a long structure (eg a fence) or at a height. Then the device can be rearranged less frequently, and only move with the holder in hand. For stationary activities, 2 meters per mass and 3 meters per holder are sufficient. For the workshop, it is better to buy 5 meters on the electrode holder.

But you cannot extend the cable arbitrarily. Increasing the length increases the resistance, which means that the current strength will decrease.

The maximum length is calculated by the formula:

Maximum welding current divided by 100 = factor.

For example, a device with an indicator of 160 A: 100 = 1.6.

The cross section of the existing cable must be divided by the resulting factor. We have a cable 1x25 mm². If 25 is divided by 1.6, then we get 15 meters. This is the maximum length that needs to be divided into mass and holder, for example 10 and 5 m. If you use a cable of 20 m, then the current from the device will decrease to 160 A. 120 A. Each increase in length adds weight, which affects the ease of transportation.

To grow the cable, apply copper crimping. This provides tight contact and no overheating. Twisting is not allowed, as it creates additional resistance.

An example of connecting a cable by crimping.

Using these tips, you will be able to choose a welding cable that exactly matches the power of the device and the challenges ahead.

Norman polymer coated metal tile - reviews and opinions on its use

The combination of wallpaper in the interior - ways and basic rules + Photos and Videos

Reviews of humidifiers Boneco Air-O-Swiss of all models: 7135, U7135, AOS U201A, P2261, W1355

Reviews about air conditioners MDV and split systems of this brand