Which underfloor heating is better suited for laminate flooring - type comparison and model overview

During the repair, you often have to compromise on the compatibility of materials and technologies. Therefore, the question of which warm floor is better to choose for a laminate is always relevant. In addition, there are several options, and the differences between them are quite significant. Therefore, choosing a floor covering, it is advisable to understand the features of heating systems.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

What kind of warm floor is better to use under the laminate

In simple terms, a laminate is a panel of pressed and glued cellulose fibers. They are protected from aggressive influences by a substrate, a decorative film and chemical additives, and are stacked without attachment to the base.

From this definition we can conclude:

- Laminated panels do not conduct heat well.

- The substrate further reduces thermal conductivity.

- The wood-fiber structure significantly expands-tapers when heated-cooled.

- With increasing temperature, toxic substances may be released.

At first glance, such a flooring is not the best choice when it comes to the need for a warm floor. However, negative factors can be, if not completely eliminated, at least minimized by observing simple conditions. For example - having bought a suitable laminate, limiting the temperature to 25-27 degrees, choosing the right floor heating system correctly.

Important: in fact, any system is suitable, but some of them seem to be created for the laminate.

Water heated floors

Electricity is the most expensive source of heat, even taking into account nightly and other preferential rates. Therefore, water fuel boilers (especially gas) are not only efficient, but also economical. In combination with laying the pipeline under the floor, this heating method is sometimes optimal.

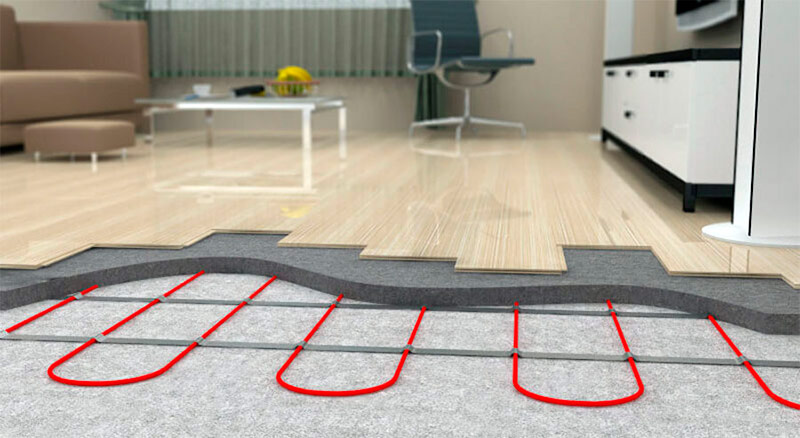

Sectional underfloor heating.

But it also has disadvantages:

- obtaining permission for installation in an apartment building is a lengthy, costly procedure;

- design, installation - labor-intensive processes requiring skills and special equipment;

- the price of stop valves is comparable to the cost of the remaining elements combined;

- laying of the pipeline involves the installation of an insulated thick layer screed;

- control, management (for example, zoning of space) is complicated by the complexity of the system as a whole;

- low maintainability associated with significant waste of time and money.

It is advisable to equip a water heated floor in a gasified private house and it is best to do this even at the stage of building a house. When installing a water heated floor during repair work, you must be prepared for a large amount of dust and dirt. As a rule, when arranging a warm floor in a private house, it is mounted in all rooms, which makes the whole system more economically feasible.

Heating electric cable

The heating (resistive) cable works on the principle of a closed conductor with unchanged resistance, which heats up when power is supplied. The section (section) ready for installation is usually wound into a bay, while the section power is calculated along the length. It is simple, reliable and inexpensive, and its efficiency depends, for the most part, on installation technology. If everything is done correctly, cable heating is quite economical, efficient, even in comparison with water. Regulators (thermostats) are also available and easy to install. Therefore, difficulties with control and management does not arise.

Arrangement of a heating cable under the laminate.

However, the disadvantages, however, are:

- system volatility;

- the need for complete immersion of the heating element in the screed;

- the need for a full-fledged “pie” device, including insulation and concrete screed;

- low maintainability;

- inadmissibility of overheating associated with overlapping of the cable or its suboptimal location relative to furniture, household appliances, etc .;

- failure of the entire section if one section is damaged.

You can say that a resistive cable is a good option. One could stop at it, however, when using it, it would be necessary to equip the concrete screed with a height of 3-5 cm. If the screed is already flooded and raising the floor level is impossible, the use of a heating cable is not advisable.

Electric heating mat

Heating mats are a fiberglass or plastic mesh on which the same resistive cable is fixed. It is twisted into rolls convenient for installation, and the canvas can be cut by adjusting to the shape of the room. The distance between the turns of the heating core is uniform and optimal here, which greatly simplifies installation.

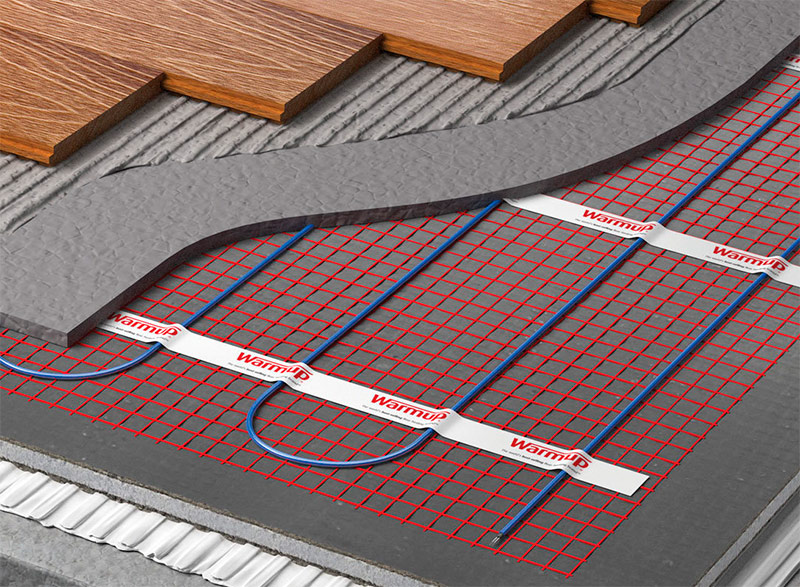

Arrangement of a heating mat under the laminate.

A major advantage of cable mats is also the compactness due to the thickness of the cable. Thin thin sections (3-5 mm) do not require the installation of a thick-layer screed. Therefore, they are often laid, for example, immediately under a ceramic tile. With the laminate, the situation, of course, is different - here you can not do without screed (1.5-2 cm thick). After all, a cable that is not immersed in an environment that removes heat will burn out.

Almost all the flaws inherent in the cable in the bay are observed in the case of heating mats.

Aluminum Electric Heating Mat

Aluminum mats are a significantly modified analogue of cable mats. Here, the heating elements are already immersed in a medium that removes heat - dense aluminum foil. The cable is not round, but flat, so there are practically no protruding parts on the working surface. A significant part of the heat is transferred in this case by radiation reflected upward by the foil. Therefore, the use of thermal insulation to reduce heat loss is optional (but desirable).

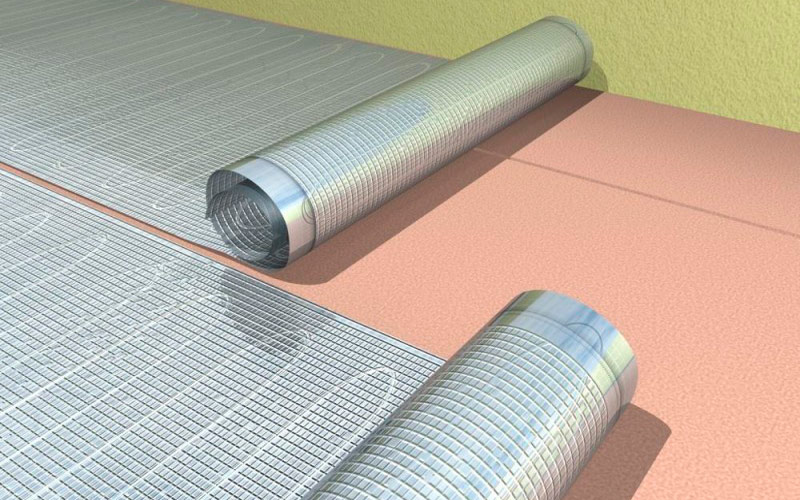

Aluminum heating mat laid on the base.

Aluminum mats are designed for laying immediately under the floor covering, which is not attached to the base. Including - under the laminate, parquet board, linoleum, etc., even in wet rooms. In any case, the complexity is minimal - spread the mats, laid the temperature sensor, connected the system to the thermostat. All main connections are made at the factory or prepared for simple and quick switching. An additional plus - a solid foil almost completely absorbs electromagnetic radiation and is a grounded circuit (if connected correctly).

The device is an aluminum heating mat.

The disadvantages of this product include the high price and, as a consequence, the likelihood of fake brands.

Answering the question, what kind of underfloor heating is better for laminate flooring, we can say with confidence that aluminum heating mats are the best solution.

Film underfloor heating

A film floor is several layers of a dense polymer film glued and twisted into a roll. On the inner surface of one of them graphite (or other carbon) markings are applied.It is a parallel strip about a centimeter wide, connected at the edges of the sheet. The web thickness is 0.5-2 mm, depending on the model, and the roll width is usually 0.5 m. This film is also called infrared, and this is explained by the fact that more than 70% of the heat is transmitted by radiation in the infrared range.

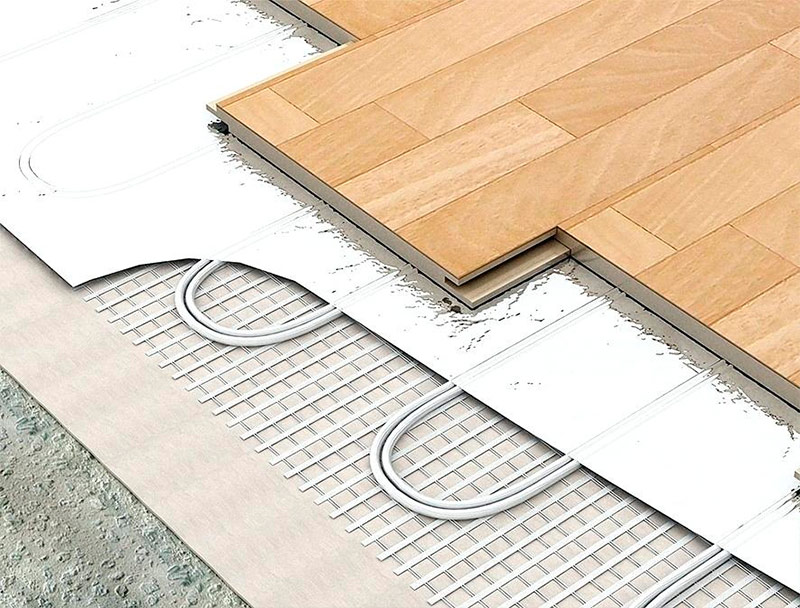

Laying a laminate on a film underfloor heating.

The main advantages of infrared film:

- compactness, lack of protruding parts;

- simplicity, speed of installation, connection;

- responsiveness of control and management;

- unnecessary additional insulation (in addition to the heat-reflecting layer);

- high heating rate of surrounding objects;

- electricity consumption is 20-30% lower than cable floors.

At the same time, the heating sections are connected in parallel, and if one fails, the others will continue to work. In addition, the film can be cut by repeating the geometric shape of the room. Therefore, installation is as simple as laying aluminum mats, but the film is more compact and, as a rule, cheaper.

The disadvantages of infrared film are standard for electric heating. For example - inadmissibility of artisanal compounds, overheating, lack of self-regulation (in most models). But low mechanical strength, inadmissibility of laying in damp rooms are added to them.

The IR film does not require the installation of a screed and fits directly under the laminate, it saves energy, but some models are not designed for use in humid rooms. However, the laminate itself is also not laid in rooms with a humid microclimate.

The best models of underfloor heating under the laminate, according to user reviews

Understanding how models of any product differ is always difficult, especially if the price and appearance do not mean anything. Here we look at several samples of underfloor heating, positively noted on the forums and in consumer reviews. To limit the amount of information analyzed, we pay attention to aluminum mats and film floors, since it is these types that are advisable to lay under the laminate.

Aluminum heating mats

Thermal Suite Alumia

Teplolux Alumia (Russia) is a system designed specifically for laying under hard coatings - laminate, parquet, OSB sheets, plywood, etc. The sample combines safety, efficiency, ease of installation and accessibility. Recommended for children's rooms, suitable for use in wet rooms.

The design of Alumia mats consists of two layers of dense foil, between which a heating element is located. Its function is performed by an ultra-thin two-core shielded cable with double insulation. The foil is finished with polyethylene lamination, which increases the strength and integrity of the system. All switching couplings are made in compliance with safety and reliability requirements. Specific power of mats - 150 W / m2Manufacturer's warranty is 12 years.

Heating mat Thermomat LP

Heating mat Thermomat LP (Sweden) - products of one of the leading European manufacturers. Significantly different from competitors in terms of energy efficiency with the same actual performance indicators. Increased safety and reliability of the system due to design features:

- A twin-core, fiberglass-reinforced cable is shielded with a double braid - solid foil and tinned copper wire;

- The internal insulation of the heating elements is made of refractory elastic Teflon;

- Cable cross section less than 3 mm;

- The aluminum foil that removes and distributes heat is reinforced with fiberglass.

Aluminum mats Thermomat LPdesigned for installation directly under the hard flooring "floating type". Including - laminate flooring, parquet, parquet board, etc.Installation is carried out in three stages: laying a heat-insulating substrate, laying mats and a temperature sensor, connecting a cable to a thermostat. You can turn on the system immediately after connecting. Additional insulation, reinforcement or fastening is not required. Specific power - 130 W / m2.

Film underfloor heating

Film heat-insulated floor of CALEO GOLD

Film heat-insulated floor CALEO GOLD (Russia) - one of the most popular infrared thermofilms in Russia. It is produced under license from the Korean concern, using Korean components.

Differs from analogues:

- the presence of a built-in silver anti-spark mesh;

- partial self-regulation of heating, which reduces energy consumption depending on temperature;

- savings of up to 30% compared to cable underfloor heating;

- high heating rate;

- combination of compactness (thickness less than 1 mm) with durability.

Thermal film is designed for laying under any floor coverings that are not fixed to the base. Including: laminate, parquet, linoleum, carpet, etc. Suitable for use as the main or additional source of heat in dry and humid rooms. The tightness and reliability of the contacts is due to the installation technology, providing for their processing with bituminous waterproofing mastic. The kit includes: thermal film, wiring accessories, documentation.

Infrared thermal film National comfort PNK

Infrared film "National Comfort" PNK (Russia) - development of the Russian company "Teplolux". Combines comfort, ease of installation, reliability and quality of production with an affordable price. Depending on the area of the premises, the products are presented in canvases of various lengths and corresponding capacities.

Features:

- The film is intended for installation in dry rooms.

- It can be used as an additional heat source or as an alternative to traditional heating appliances.

- It is laid directly under the floor covering.

- 7 year warranty.

- The kit includes film, documentation, mounting cable elements.

Film infrared heating Electrolux ETS 220

Film infrared heating Electrolux ETS 220 (Sweden) - heated floors produced by one of the oldest concerns in Europe. The ETS 220 series thermal film combines quality, power, economy, affordable price and an innovative approach. The heating elements here are made of carbon.

The film is designed for installation in dry rooms, suitable for year-round use. Performs the functions of the main or additional, comfortable, heat source. It is laid immediately under the “floating” type flooring - laminated floors, linoleum, parquet, etc. Not suitable for systems including ceramic tiles, porcelain stoneware, marble, etc.