Types of radiators, their advantages and disadvantages

In summer, you need to cook not only sledges, as in the old saying. It is worth taking care of other attributes that save us from the winter cold. This period is best suited for changing radiators. But before changing them you need to decide on their type and type. To facilitate your choice, we have classified the main types of radiators and indicated their main characteristics, advantages and disadvantages.

Steel heating radiators

Panel Steel Radiators

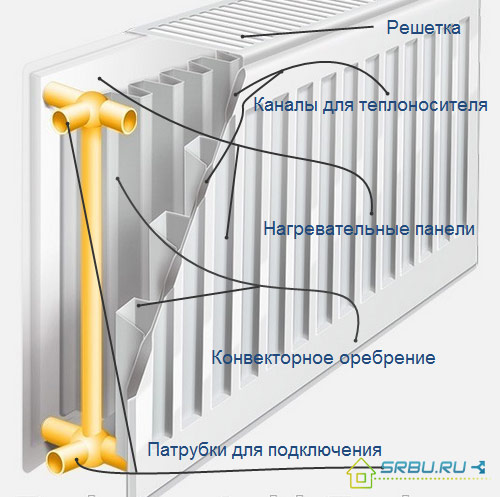

Such radiators are also called convectors; they have high efficiency - up to 75%. Inside the radiators is one or more steel heating panels and convector fins.

The device steel panel radiator.

Panel radiators are the most budgetary solution for your own home and therefore are the most common in autonomous heating systems. Depending on the number of heating panels and convection fins, the following types of panel-type water heating radiators are distinguished: 10, 11, 20, 21, 22, 30, 33.

Manufacturers: These are mainly European countries - Germany (Buderus and Kermi), Czech Republic (Korado), Italy (DeLonghi), Finland (PURMO). Their prices are not high, so Russian manufacturers are not very well represented in this market.

+ Pros:

- Inertia is low, heat transfer is excellent.

- The coolant volume is small, energy consumption is small.

- These radiators are environmentally friendly and harmless, so they can be used in hospitals, schools and kindergartens.

- Extremely low price.

- Minuses:

- If water is drained from the heating system, then when oxygen comes into contact with the walls of the radiator, corrosion begins to form.

- Water hammer is dangerous for steel radiators. Therefore, they cannot be used in multi-storey buildings.

- Due to convection, drafts and the raising of fine dust are possible.

Tubular steel radiators

The design of the radiator is a construction of steel pipes through which hot water passes. The production of such devices is more expensive than panel ones, therefore their price is higher.

There are many design options - this is a real feast for the imagination of the designer.

Manufacturers:

Of the European manufacturing countries, Germany (Kermi, Charleston, Zehnder Charleston, Arbonia) and Italy (Israp Tesi) can be called. Domestic devices manufactured by the KZTO plant (Kimry) have a working pressure of up to 15 bar. And the “RS” and “Harmony” models are also protected from corrosion by a polymer coating.

Pros and cons: These radiators, as well as panel ones, have advantages and disadvantages inherent in steel products. However, in terms of pressure, their indicators are better (this is a plus), and their price is significantly higher (this is a minus).

Key Features

- Pressure (working) - an average of 6-10 bar (for panel radiators) and 8-15 bar (for tubular radiators).

- Thermal power (total) - 1200-1600 watts.

- Hot water temperature (maximum) - 110-120 degrees.

- The pH of the water is 8.3-9.5.

Aluminum heating radiators

As the name implies, these are radiators made entirely of aluminum. There are two types of radiators - injection molding and extrusion. Both of them are better used for autonomous heating - they are not suitable for a centralized system due to pressure and corrosion, which is caused by poor-quality coolant in the central heating system.

Injection radiators

Die-cast radiators feature wide channels for hot water and sturdy thick walls.

The radiator is composed of several sections, which, if necessary, can either be added or removed.

Extrusion radiators

With this production method (cheaper), the vertical parts of the battery are extruded from an aluminum alloy on an extruder. The collector is cast from silumin. The whole product cannot be changed - you can neither add sections nor remove them. This is the main disadvantage of this type of radiator.

Manufacturers: These are mainly companies from Italy. In particular, FARAL Green HP, ALUWORK, Sira Group (ROVALL batteries), Fondital can be called.

+ Pros:

- These radiators are very lightweight, so they are simply mounted without requiring the use of durable brackets.

- In terms of heat transfer, they occupy one of the first places among all heating devices.

- They can heat a room very quickly.

- They are economical and can be equipped with a temperature controller.

- Product design is modern and attractive.

- Minuses:

- The service life is not very long - about 15 years.

- Aluminum is chemically active, therefore it suffers from corrosion and requires a high-quality coolant.

- When air is displaced, hydrogen is formed.

- Weak convection.

- Leaks between sections are possible.

- Aluminum radiators are not able to withstand water hammer and pressure surges.

Key Features

- Pressure (working) - an average of 6-16 bar.

- Thermal power (1 section) - 82-212 watts.

- Hot water temperature (maximum) - 110 degrees.

- the pH of the water is 7-8.

Cast Iron Heating Radiators

Conventionally, they can be divided into conventional or modern-style radiators and retro-style radiators.

Cast iron radiators in a modern style

The oldest type of radiator. These radiators are distinguished by simplicity and severity of forms, flat facade, neat design. They bask for a long time, but they withstand all the hardships of central heating with honor. They are durable, cheap, serve about 50 years. Therefore, when deciding which types of heating radiators to choose, many dwell on cast iron ones.

Manufacturers: Budget, cast-iron radiators are produced by Ukrainian, Russian, Belarusian plants. But foreign products will be both better in quality and more attractive in appearance. We note the companies Konner, Viadrus, DemirDöküm, Roca.

Retro style radiators

Each of these radiators is a small masterpiece. Indeed, cast iron art casting looks very elegant, decorating any room. Unfortunately, each such battery is very expensive.

Manufacturers: These are firms from England, Germany, France, Turkey, China. For example, Roca and Konner produce very beautiful models.

+ Pros:

- They are able to work for at least 50 years.

- Cast iron is chemically passive; therefore, it is "too tough" for corrosion.

- Radiation radiation warms up a room with high ceilings.

- When the heating is turned off, the batteries remain hot for a long time.

- Low price (except for models made by art casting).

- Minuses:

- Long warm up.

- The large weight and dimensions cause difficulties in transportation and installation.

- Radiators need a solid mount.

- A large volume of coolant.

- Cast iron is a brittle metal. A water hammer is capable of breaking a cast iron battery.

Key Features

- Pressure (working) - 9-12 bar.

- Thermal power (1 section) - 100-160 watts.

- Hot water temperature (maximum) - 110 degrees.

Bimetal heating radiators

Such radiators combine a tubular core of steel and an aluminum shell. Basically they are made of sections, an even number.

But there are also integral (monolithic) models (they are rarely found on sale), plus of which - the ability to withstand up to 100 atmospheres of pressure. In the case of monolithic models, a strong steel frame is created, on which the aluminum shell is “dressed”.

The device is a bimetallic radiator.

Completely bimetallic radiators have a steel tubular core along the entire length of the radiator channels. They are reliable and durable, but are expensive. Good radiators are made by Rifar (Russia), Royal Thermo BiLiner and Global Style (Italy).

Pseudo-bimetallic radiators are called, which have only vertical channels reinforced with steel. They are cheaper than the previous ones, by 20 percent, they give out heat better, but are more sensitive to corrosion due to the contact of the coolant with aluminum.Such products are made by Rifar (Russia), Sira (Italy) and Gordi (China).

+ Pros:

- Inertia is practically absent, heat transfer is great.

- Bimetal can withstand high pressure and water hammer.

- The volume of hot water is small.

- Installation is simple, design is modern.

- Resistance to corrosion.

- Minuses:

- The price is "biting."

- Heat dissipation is lower than aluminum radiators.

Key Features

- Pressure (working) - an average of 20-50 bar.

- Thermal power (1 section) - 150-180 watts.

- Hot water temperature (maximum) - 130 degrees.

- Heat transfer characteristics - it doesn’t matter.

Floor convectors

A new solution among heating appliances is convectors hidden in the floor, consisting of a heat exchanger, duct and a decorative grill. The pipes for the coolant are copper, and the ribs are aluminum. There are models with a steel tubular core ("Breeze" from KZTO). Particularly good floor radiators for panoramic glazing. They are used at airports, car dealerships, sports facilities (for example, swimming pools).

+ Pros:

- Strength and simplicity of construction, light weight.

- They are not subject to corrosion.

- They take up little space.

- They are practically invisible.

- Easy to install and clean.

- The uniformity of the heating of the room.

- Protect from fogging of glasses.

- Minuses:

- Big assembly length.

- Inability to use forced ventilation.

- Low heat loss.

- Uneconomical.

Manufacturers: OPLFLEX (Czech Republic), Mohlenhoff (Germany), JAGA (Belgium), IMP KLIMA (Slovenia), KZTO (Russia).

Key Features

- Pressure (working) - 10-16 bar.

- Thermal power - 130-10000 watts.

- Hot water temperature (maximum) - 110-130 degrees.

Plinth heating convectors

These convectors, called still warm skirting boards, are very low. Only 20 or 25 cm. And their depth is even less - 10 cm. With us they have not yet taken root, but in America they are very popular. They are mounted on the wall.

+ Pros:

- Fuel savings on heating - up to 40 percent.

- The presence of temperature controllers, protection against overheating.

- Quick installation, easy repair.

- Uniform heat distribution.

- Minuses:

- Installation is carried out only by specialists.

- Due to the fit of the convector to the walls, their finish is warped.

- High price.

Key Features

- Thermal power - 500-1500 watts.

- The temperature of the coolant is up to 130 degrees.

- Maximum working pressure up to 16 atm.

Now, having learned about the types and advantages of different types of heating radiators, you can choose the necessary radiators more confidently and correctly.