Reviews about heating boilers

Modern heating boilers are technically quite complex devices. Therefore, even for the same type of models, which are marketed as interchangeable products, there can be a significant spread in the main technical and operational characteristics, not to mention the cost. Reviews of people who already use this product will help to understand the intricacies of the device and the effectiveness of various models of heating boilers.

Types of boilers by type of fuel

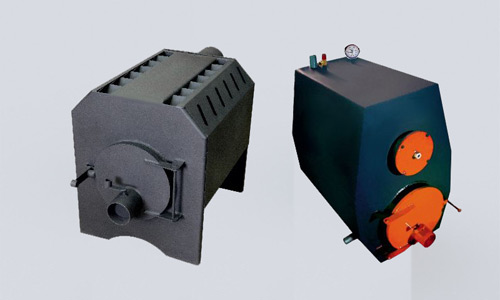

Solid fuel boilers. A lot of modifications are produced, from the most primitive bourgeois to the heating systems on pellets with remote control via GSM.

The main types are:

- Classical;

- Long burning;

- Gas generating (pyrolysis);

- Pellet.

Oil boilers. This view is also presented in a wide range of control systems from primitive mechanical to modern electronic. In turn, liquid fuel boilers are divided into those using diesel fuel and mining: oil, fuel oil, various biological oils.

Electric. The most simple to install and connect. They have a very high level of automation and many management functions. The highest efficiency of all types of boilers. But they are very sensitive to the reliability of the power supply system.

Gas boilers. One of the most efficient and most economical heating system devices.However, they can only be used if it is possible to connect to the central gas supply system. In addition, serious restrictions are imposed for use in dwellings of old-built apartment buildings.

Combo devices. These are boilers that can use several types of fuel after a small upgrade or without it. Usually these are variations using solid fuels: firewood or coal and electricity or gas.

Criteria for choosing a heating boiler

Efficiency - Naturally, the higher it is, the better, but although this indicator is the key, the effectiveness of controlling the heating system also affects the possibility of its implementation.

One and two-circuit models are devices that heat large rooms, as a rule they have one circuit, this is due to the need to use the entire boiler power for heating. To heat small areas and rooms with good thermal insulation, the power of even very compact devices is enough, so they can be equipped with an additional heat exchanger for the domestic hot water system.

Boiler power - 1 kW is usually taken to heat 10 m2 of a room with a ceiling height of not more than 3 m. However, this indicator is quite subjective, it can be affected by the quality of building insulation and the efficiency of the wiring of heating radiators. In addition, a 10-15% power reserve for peak network loads should be provided.

Product durability - directly depends on the material of the heat exchanger and the combustion chamber. However, the timeliness of maintenance has a great influence on this indicator, whether the boiler is operating at the limit of capabilities and the intensity of functioning, as well as the correct initial installation and piping of the boiler, made by specialists.

There are many secondary criteria, which, nevertheless, significantly affect the functioning of the heating system and the cost of its installation and configuration:

- Chimney or parapet type of removal of combustion products;

- Open or closed combustion chamber;

- Combustion air is taken naturally or forcedly, the type of ventilation with which the boiler room should be equipped depends on this.