What is the difference between FC plywood and FSF and their scope

In construction, especially in house building, as well as in the manufacture of wooden products, plywood FC and FSF are very often used. Knowing their properties and the distinctive characteristics described below will help you make the right choice.

The difference in the production of FC and FSF plywood

Any plywood consists of three or more layers of peeled wood (veneer), oriented perpendicularly or at an angle to each other (to give greater strength) and connected by an adhesive. Veneers are most often made from birch or pine, although in some cases other (usually hardwood) wood species are also used.

This or that combination determines the type of plywood according to the material, that is, it happens:

- birch (all veneer layers are formed from this tree);

- coniferous (veneer exclusively pine);

- combined (middle layer - pine, outer - birch or alder).

In appearance, plywood is divided into grades (E, I, II, III, IV), according to the degree of water resistance - to grades (FC and FSF), according to the degree of mechanical surface treatment - to polished or unpolished.

Grade E1 is considered to be elite, that is, the surface should be perfectly smooth and clean, without knots, rot, caverns and other defects. The lower the grade, the lower the requirements for appearance and marriage. 4th grade, for example, may contain an unlimited number of knots per unit area.

Plywood can be either unpolished (NS) or polished on one or two sides (Ш1 and Ш2, respectively).

The degree of water resistance determines the brand of plywood: FC (waterproof, for internal use) or FSF (high water resistance, for indoor and outdoor use).

If all of the above applies to both brands of plywood, then the adhesive composition for them is prepared using different technologies. It is he who is encrypted in the abbreviation and has a decisive influence on the water resistance of the plywood sheet.

FC means that it is plywood "F" of usual water resistance, and urea-formaldehyde glue (K) is used in its production. Hardwood is usually used to make this plywood (conifers are much less common).

Plywood FC.

FSF deciphering in a similar way: "F" is again plywood, and the letter combination "SF" indicates the presence of resin formaldehyde glue, which provides increased moisture resistance.

Plywood FSF.

Comparison of FC and FSF plywood

Visually distinguishing one brand of plywood from another is quite difficult. Only with a very careful examination of the adjacent sheets will it be possible to notice that in the section of the FC there is a lighter color of the interlayers, close to the veneer color. The FSF sheet is glued with another, darker glue with a slightly reddish tint.

However, if you manage to make a visual difference, it does little. It is much more important to know the qualitative difference, which, ultimately, will be the determining criterion in the matter of “FC or FSF”. These criteria are reduced to the following indicators.

| |  |  |

|---|

| Plywood FC |

Plywood FSF |

| |

| Origin of veneer |

Coniferous, deciduous varieties, birch |

Coniferous, deciduous varieties, birch |

| Glue |

Urea formaldehyde |

Phenol formaldehyde |

| Phenol content |

Not contained |

8 mg / 100 g |

| Bending strength |

40 MPa |

60 MPa |

| Moisture resistance |

Standard humidity level of residential or non-residential premises |

Maximum humidity level of external conditions, work with materials containing water |

| Environmental friendliness |

higher |

below |

| Decorative |

it's better |

worse |

| Price |

below |

higher |

Bending strength

In this parameter, the FSF is almost one and a half times higher than FC (60 MPa versus 45 MPa).It not only withstands higher loads, but also has better resistance to wear and mechanical damage.

Moisture resistance

Moisture resistance - here FSF surpasses its counterpart due to the use of formaldehyde glue. Although after wetting it swells, after drying its properties, shape and appearance are restored in almost full volume (it is understood that we are not talking about the prolonged stay of plywood in a wet state). FC in this respect is more sensitive: under the influence of moisture, it delaminates and / or curls.

Environmental friendliness

Here FC takes a priority position, since its adhesive base does not emit phenols (it simply does not have them). But in the FSF, they are present in an amount of 8 mg per 100 g. Although this concentration is not critical for human health (phenol emission class E1), it is still considered undesirable for residential premises, especially if children are in them.

Decorative

The decor for both types of plywood is approximately equivalent and depends primarily on the variety characterizing the presence (absence) of defects, knots, foreign inclusions and other flaws on the sheet surface. Although due to the specific shade, which is slightly noticeable on the FSF sheets due to the presence of formaldehyde resin, the picky esthete is likely to give preference to FC.

In conclusion, it is worth noting the higher cost of the FSF, which should also not be discounted.

Fields of application for FSF and FC plywood

Despite the above differences between FC and FSF, there are many areas where it is possible to use both one and the second brand. At the same time, there are areas where it is allowed to use only one of the categories considered. In particular, FSF is required where it is necessary to ensure strength and moisture resistance, and FC preference is given when factors such as environmental friendliness, appearance and price come to the fore.

FSF plywood is ideal for the manufacture of the following structures and products:

- formwork;

- external cladding of frame buildings;

- outbuildings;

- roof lining;

- street advertising (billboards, signs, etc.);

- sports facilities in the playgrounds;

- garden furniture.

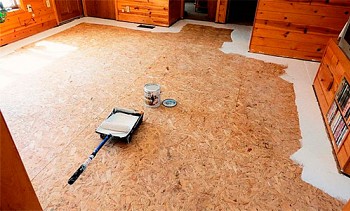

It is advisable to use FC plywood for the following purposes:

- facing of internal walls and ceilings (except for kitchen and bathroom);

- a substrate for a laminate or parquet;

- furniture for enclosed spaces (home, office, store, warehouse, etc.);

- making musical instruments;

- creation of decorative elements;

- production of containers (boxes, boxes, etc.).

Marking

For a full qualitative assessment, marking is applied to the plywood sheet or tag, by which you can find out its main characteristics.

For example, the inscription “Plywood FSF 1/2 E1 Ш2 1500х1500х9 GOST 3916.2-96 pine” means that the plywood is made of pine veneer with a formaldehyde resin sizing, with surfaces of the 1st and 2nd grade (front and back), the first class of phenol emission, with double-sided grinding, 9 mm thick, 1500x1500 mm in size, produced according to the specified GOST.