OSB cooker: harm to health and environmental friendliness of the material

Oriented strand boards (abbreviated as OSB, although at least, if not more often, use OSB - transcription of the English abbreviation OSB - Oriented Strand Board) are increasingly replacing their main competitor - plywood - from the market of composite wood building materials.

The wood content in the OSB is 90-95%, the remaining 5-10% are water-resistant adhesive. And the name component of the glue has become a stumbling block for many ordinary users. Despite the high annual growth rate of OSB production, disputes over the safety of using this material do not subside. So today we’ll talk about the environmental friendliness of OSB boards.

Content:

- What harmful substances are contained in the OSB and how do they get there

- What is the danger of formaldehyde and what are the standards for its concentration in air

- Formaldehyde content in OSB boards and limits

- How to choose an environmentally friendly OSB board

- Methods of protection against toxic fumes

What harmful substances are contained in the OSB and how do they get there

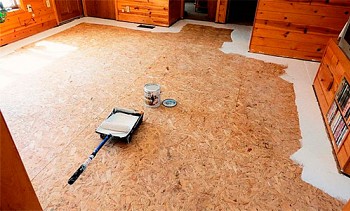

These plates are made by thermal pressing of large-sized shavings (small chips) of coniferous wood laid in layers and oriented in layers. The multidirectional orientation of the chips in different layers provides increased strength and stiffness of the material, so OSBs are widely used in construction (sheathing of house frames, flooring of rough floors, formwork, manufacturing of SIP panels), in furniture production, in the manufacture of containers, etc. .

In the production of OSB boards, special adhesives are used as a binder pulp, the main components of which are various synthetic resins - melamine-formaldehyde, urea-formaldehyde or phenol-formaldehyde. The name of all these resins makes it easy to guess that one of the reagents in their synthesis is formaldehyde. This means that each resin, depending on its quality, contains a certain amount of unreacted aldehyde.

Free formaldehyde can also be released as a result of the partial depolymerization of the resin, which occurs under the influence of high (up to 200 ° C) temperature, at which the process of pressing the chips impregnated with glue is carried out. A significant part of this toxic substance will evaporate already in the production halls, but the residues will “ooze” from the finished stove for a long time: the level of formaldehyde emission will be halved by about half a year from the moment of production.

Formaldehyde is also released during the operation of OSB boards: the slow destruction of formaldehyde resins (and, in the first place, less stable urea-formaldehyde resins) may be due to various adverse environmental factors - moisture, high temperature, and ultraviolet rays.

In fairness, it should be noted that the source of formaldehyde can be not only synthetic resin, but also the wood itself, traditionally considered the standard of environmental friendliness. Formaldehyde emission from freshly harvested wood can reach 0.2 mg / m3. With proper drying of lumber, this figure decreases and becomes significantly lower than the background created by low-quality synthetic glue.

What is the danger of formaldehyde and what are the standards for its concentration in air

What is formaldehyde, and is it really so harmful to human health or are these the next horror stories of competing marketers?

Formaldehyde (aka ant aldehyde) is a colorless gas with a pungent odor, relatively stable at 80-100 ° C and slowly polymerizes at temperatures below 80 ° C.It has been widely used in various fields of the national economy: in the chemical industry - for the production of plastics and artificial fibers, in the construction industry - for the production of varnishes, paints, polyurethane foam, linoleum, various wood-shaving plates (chipboard, OSB, MDF, plywood) and as an antiseptic for wood processing, in the leather industry - as a tanning agent, in agriculture - as a fumigant for grain storage, etc.

With short-term exposure to high concentrations of formaldehyde vapor (1.2 mg per cubic meter of air), irritation of the upper respiratory tract, skin, mucous membrane of the eyes is observed, the first signs of damage to the central nervous system (headaches, dizziness, weakness) appear. The daily effects of small concentrations of formaldehyde on the human body for a long time are the cause of chronic rhinitis, chronic bronchitis, obstructive pulmonary disease, bronchial asthma. In addition, formaldehyde is a carcinogen: with prolonged contact with its vapors, the risk of developing cancer of the nasopharynx increases significantly.

In accordance with the sanitary and hygienic standards SanPiN 2.1.2.1002–00 and GN 2.1.6.1338–03 approved by Russian legislation, the maximum permissible concentrations of formaldehyde in indoor air are:

- maximum one-time (maximum concentration limitmr) - 0.05 mg / m³ (exposure 30 minutes),

- daily average (MPCss) - 0.01 mg / m³.

The value of a single MACmr) corresponds to the maximum concentration of a substance in the air, at which there are no reflex reactions of the human body to contact with this substance. The value of the average daily MPC (MACss) denotes the limits of concentration within which the substance does not directly or indirectly harm human health under conditions of continuous inhalation for an indefinitely long period of time. At formaldehyde vapor concentrations below MACss You can not be afraid of the appearance of any pathological changes in the body. The substance does not have a general toxic, carcinogenic or mutagenic effect at such concentrations.

It should be noted that the requirements of the World Health Organization (WHO) are less stringent: the limit of safe concentration of formaldehyde is defined by its regulatory documents as 0.1 mg / m³ with a single exposure of not more than 30 minutes.

Formaldehyde content in OSB boards and limits

European standard EN 717-1, developed by the European Committee for Standardization, oriented particle boards are divided into two classes according to the level of formaldehyde emission measured in the climate chamber:

- E1 - up to 0.125 mg / m³;

- E2 - from 0.125 to 1.25 mg / m³.

The previously existing class E3, characterized by a formaldehyde emission level of 1.25 to 2.87 mg / m³, is not used today; the production of plates corresponding to class E3 is prohibited in Europe. Currently, the issue of introducing a new class of materials - E1-plus - with a limit value of formaldehyde emission of 0.080 mg / m³ is actively discussed, which means that it is possible that OSB boards with a new marking will appear soon.

Formaldehyde emission is directly related to the content of this substance in the material. In accordance with European standards EN 120 and EN ISO 12460-5, the formaldehyde content (in mg per 100 g of an absolutely dry OSB board) for the classes indicated above is:

- E1 - up to 8 mg;

- E2 - from 8 to 30 mg.

On sale you can find OSB-boards with the marking E0. This class, characterized by a formaldehyde content of less than 5 mg per 100 grams of dry stove, is not standardized, but sometimes this designation is still used for advertising purposes.

Russian GOST R 56309-2014 suggests the division of all OSB-plates into three classes, depending on the level of formaldehyde emission:

- E0.5 - up to 0.08 mg / m³;

- E1 - from 0.08 to 0.124 mg / m³;

- E2 - from 0.124 to 1.25 mg / m³.

The formaldehyde content in OSB boards corresponding to these classes is:

- E0.5 - up to 4 mg per 100 grams of dry plate;

- E1 - up to 8 mg;

- E2 - from 8 to 30 mg.

As you can see, the requirements of modern Russian standards are no different from European ones.

The above figures apply only to OSB, but not to other plate materials (plywood, particleboard, MDF, HDF). The production technology of the listed wood boards is different, therefore their characteristics differ (and, consequently, the areas of their application). For example, if for OSB the content of formaldehyde of 8 mg per 100 g of dry material is considered normal, then in the case of chipboard it is impossible to reduce this figure below 10-14 mg. In general, OSB are champions among other wood-based panels in terms of their environmental friendliness.

This is due to the fact that in OSB there is no fine-grained chips and wood dust, and this allows us to reduce the amount of glue used (the formaldehyde content in the finished plate also decreases). Thus, the question of the health hazard of OSB boards in the context of comparing them with other wood-shaving materials seems somewhat far-fetched.

Chips for making OSB.

Chips for chipboard.

But back to the numbers. Now we know everything about the emission of formaldehyde by OSB-boards manufactured in accordance with the requirements of the standards, and the MPC of formaldehyde in the air of residential premises, it remains to compare these values with each other. By comparing the figures, you will find that formaldehyde emission even by the most environmentally friendly OSB-plate, which complies with the strict requirements of class E1, is much higher than that established in the sanitary and hygienic standards.

Of course, the idea that uncovered OSB-boards should not be used for interior decoration of premises is somewhat reassuring, as they are simply not intended for this. Coatings of various kinds isolate the panels, preventing the release of harmful substances to the internal environment of the house. In addition, it should be expected that, as the age of the house increases, the level of formaldehyde emission will gradually decrease (although measurements at real facilities have shown that this usually takes several months).

Over the past two decades, manufacturers have been able to significantly reduce formaldehyde emissions by OSB boards, experts predict a further improvement in the environmental performance of the material. This is achieved primarily by replacing chemically unstable urea-formaldehyde resins with more inert phenol-formaldehyde resins and introducing fillers into the resin composition that increase their chemical resistance.

Some manufacturers abandoned the use of formaldehyde-containing resins and switched to the production of OSB based on another binder - polymer methylene diphenyl diisocyanate. However, the transition to non-formaldehyde adhesives is more of a marketing move, designed to replace formaldehyde, which has been discredited in the eyes of the general public, with another substance that is no less dangerous to health, but at the same time less known to ordinary consumers, and therefore does not cause much panic.

How to choose an environmentally friendly OSB board

As we have seen, the safety of even high-quality OSB-boards raises some doubts, let alone cheap fakes. Unfortunately, often manufacturers in an effort to reduce the cost of production go for a deliberate violation of technology, which negatively affects the quality of products. The level of formaldehyde emission by stoves made using the cheapest and low-quality resins or in violation of the technological process regulations, often just rolls over.

When purchasing materials for building, repairing or making furniture yourself, ask the seller about the characteristics of the stove. First of all, you should be interested in the formaldehyde emission class, which reflects the amount of harmful emissions into the atmosphere. Undoubtedly, preference should be given to products that meet the stringent requirements of the E1 standard.OSB-boards of class E2, which are less environmentally friendly, are prohibited in our country for use in children's rooms, and in Europe for the manufacture of any furniture. If you are not limited in finances, you can search for sale OSB-boards of class E0 (sometimes they are labeled “Super E”). They are practically odorless, and in terms of formaldehyde content they hardly differ from natural wood.

Feel free to request documentation for the material you purchase. The formaldehyde content in OSB should be indicated in the appendices to the Certificate of Conformity. Having familiarized yourself with the section “Sanitary-and-epidemiological conclusion”, you will find out what concentration of this or that harmful substance will be established over time in an unventilated room where the material is located.

However, the presence of a certificate is not always an indicator of the integrity of the seller, and therefore the environmental friendliness of his product. Trust should be aroused by serious, time-tested companies.

You can determine very poor quality products on your own. Pay attention to the smell of the OSB that you plan to purchase. A good stove should not exude a pungent smell of formalin (by the way, and any other unpleasant odors, too). It is better to conduct an odorological examination of the material not in a cold warehouse, but in a warm, unventilated room, immediately after opening the package.

Methods of protection against toxic fumes

No matter how high the OSB environmental class is, formaldehyde emissions will still be. It is difficult to reduce the potential harm of OSB boards to health to zero, but it is possible. The rules are simple:

1. If possible, you should generally avoid using OSB-boards (like other types of engineered wood - fiberboard, chipboard, MDF, plywood, artificial laminate) for interior decoration and furniture.

2. In the presence of such materials in the construction or interior decoration of the house, their isolation from the living environment is required by coating with other materials (painting in several layers, puttying followed by wallpapering, facing with ceramic tiles, etc.). This will help reduce the concentration of formaldehyde and other harmful substances in the living area.

3. The concentration of formaldehyde in air increases with increasing temperature and humidity. Avoid waterlogging and excessive heating of wood-shaving materials.

4. Properly equipped and well-functioning supply and exhaust ventilation will help reduce the concentration of formaldehyde in the air in a living space. Carefully ventilate rooms where there is a potentially hazardous finish daily.