The best manufacturers of mineral wool - market overview

Mineral wool - a heater in demand in all areas of civil and industrial construction. It is used for insulation of walls, floors, ceilings, roofing, attic and basement structures. This article will review the best manufacturers of mineral wool and their products. We hope this helps you find the material that is suitable for heat-preserving properties, purpose and price.

The selection of manufacturers was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

Features and types of mineral wool

The term "mineral wool" is used as the general name for any fibrous insulation of inorganic origin.

There are three varieties of this thermal insulation material:

- Stone or basalt wool. It is made from a melt of rocks of volcanic origin.

- Glass wool. It is made from sand, quartzite - a raw material that is used to produce glass.

- Slaggy. The product is of poor quality from waste from metallurgical production; at present it is not used for warming residential buildings.

The application features of each of these products are regulated by state standards GOST 31913-2011. In modern housebuilding, two heat insulators are used - glass and stone wool. They differ in composition, technical properties, price, because they have different manufacturing techniques.

Slag wool is currently not used for warming residential buildings, so the features of this material will not be considered in the article.

Pros and cons of glass wool

Glass wool was named for its composition - in the manufacture of products the same components are used as for the production of glass: sand, soda, limestone, borax. The components are mixed, melted at t = 1400 ° C, filtered, binder polymers are added to them.

The mass rotates in a centrifuge until thin fibers are obtained - glass fibers, which together with polymerizing additives form a loose material suitable for insulation. After polymerization, the finished product is cooled, molded, cut and packaged for sale.

+ Glass wool pluses

- Low price. For production, cheap raw materials are used, manufacturing technology is also not expensive. The result is an economy class product.

- Light weight. The density of glass wool is lower than that of stone. The roll weighs less, therefore, gives an insignificant load on the building structure.

- Fire resistance. This is a non-combustible insulation that can withstand temperatures up to + 400 ° C without structural changes.

- Convenience of transportation. The loose structure of glass wool allows you to compress its volume several times, easy to move, transport. After delivery and unpacking, the volume of glass wool is restored.

- Chemical inertness. Glass wool is chemically passive, does not oxidize, so it is used for thermal insulation of metal structures, for example, LSTK.

- Elasticity. The flexibility of glass wool is explained by the structural features. It consists of many thin and long fibers connected by polymer binders. It is convenient to insulate structures with complex geometric shapes and hard-to-reach areas with plastic rolls of glass wool.

- Good soundproof performance. They are higher than that of mineral wool.

- Cons of glass wool

- Shrinks over time.This is explained by the fact that the quartz-glass fibers included in the composition completely crystallize over time, and glass wool gradually decreases in volume during changes.

- It splits into small fibers that are harmful to inhalation. It is impossible to breathe air with fiberglass particles, so for work it is necessary to wear a respirator, mittens, clothes made of thick fabric, safety glasses.

- Thin debris causes severe itching on the skin.

- Thermal stability of glass wool is lower than mineral wool. It loses its properties on fire if t is above 450 ° C.

- Currently, glass wool is used for insulation of building structures, the operation of which takes place in the temperature range from -60 ° C to + 450 ° C.

Advantages and disadvantages of stone (basalt) wool

Stone or basalt, in today's construction market is in high demand. It is produced by the method of high-temperature melting of stony rocks of volcanic origin, mainly basalt. The rocks melt at t above 1500 ° C, as a result of which they are stratified into fine fine fibers. Then a polymer binder is added to the mass.

After the mixture cools down, a soft fibrous insulation of a certain density is formed. Due to the large amount of air between the fibers, it retains heat well and is widely used as a building heat insulator.

+ The advantages of stone wool

- Fire resistance. Since stone mineral wool is a product from basalt non-combustible rocks, it steadily tolerates t up to + 1000 ° C without changing its structure. No harmful vapors are released.

- A variety of species by density, purpose, price. The construction market is represented by mineral wool of different densities, which are produced by the manufacturer in soft rolls or hard plates. Depending on the density of the heat insulator, it is used in different designs, solving diverse tasks - for insulation of ceilings, walls inside or outside buildings, basements or attics.

- Durability. The service life of stone wool, subject to operating rules, is about 50 years. In practice, mineral wool lasts longer.

- Form stability. Basalt insulation keeps its shape well, it is more resistant to shrinkage than glass wool. This is explained by the fact that the fibers of stone mineral wool are multidirectional, this gives the heater a greater rigidity.

- Water resistance combined with vapor permeability. The fibrous structure passes wet pairs - mineral wool “breathes”, but does not absorb moisture from the air.

- Environmental friendliness. This is an environmentally friendly building material. During installation, the fibers do not scatter, do not cause irritation on the skin of people.

- Chemical passivity. Due to this property, mineral wool can be used for thermal insulation of metal structures.

- Cons of stone wool

- Stone wool prices are higher than glass wool. For home insulation using stone wool, the homeowner will have to pay more than for cheap glass wool.

- Most brands of stone wool do not shrink, making them harder to transport.

The best manufacturers of mineral wool. Product Overview

The leaders in the ranking of mineral wool are brands Paroc, Rockwool, TekhnoNIKOL, ISOVER, URSA. The quality of the thermal insulation products of these brands corresponds to international DIN standards and Russian GOST.

Paroc

Paroc is a world-famous manufacturer of mineral wool insulation, producing energy-efficient materials with good soundproofing properties for more than 80 years. Minvata Paroc is used not only in private housing construction, but also on an industrial scale - in shipbuilding, for the production of sandwich panels, at oil and gas facilities. The company's plants are located in many countries, including Russia.

Types of mineral wool produced: stone wool.

Release form: plates, lamellas.

Overview of brands of mineral wool manufactured by Paroc

- Universal building insulation is marketed under the brand name Paroc eXtra: Paroc eXtra Light, Paroc eXtra Plus, Paroc eXtra Smart.

- Minvata for insulation of baths / saunas has a foil layer called Paroc Smart Sauna.

- Thermal insulation for walls there are three types of InWall, WAS and WAB.

- For stucco facades, the Fatio and Linio models are designed.

- For heat insulation of ceilings and floors, Paroc CGL 20 is suitable.

- For thermal insulation of the foundation, soil floor, PAROC GRS 20 is used.

- Flat roof insulation is carried out using Paroc ROB, Paroc ROL or Paroc ROS.

- There is a special purpose insulation - fireproof Paroc FPS and windproof soundproofing products Paroc SSB.

- All Paroc products are packaged in consumer-recognizable red and white PVC packaging.

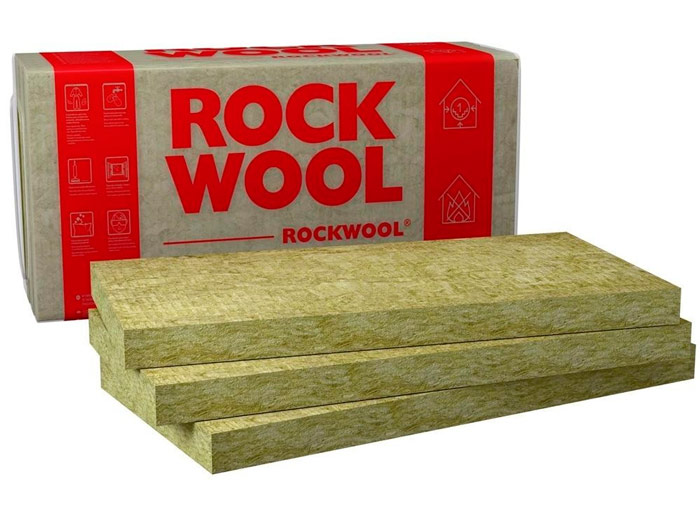

Rockwool

Rockwool (Rockwool) is an international company headquartered in Denmark, with factories in 18 countries producing high-quality mineral wool insulation. The company produces an extensive line of heat-insulating and noise-insulating materials for private housing construction. For the convenience of customers, the manufacturer clearly delimited the products into categories depending on the purpose, giving each type an easily recognizable name.

Types of mineral wool produced: basalt cotton wool.

Release form: slabs.

Rockwool mineral wool brand overview

- Walls are thermally insulated with Rockwool Scandic or Light Butts.

- For external ventilated facades or LSTK, it is recommended to use the Light Butts Extra multi-functional mineral wool.

- The floor and ceiling are insulated with plates with the sound-absorbing effect of Rockwool Acoustic or Scandic mats.

- For thermal insulation of baths / saunas there is Rockwool Sauna Butts.

- The fireplace is isolated using Rockwool Fireplace Minerals.

- For attic, pitched roofs, Rockwool Scandic or Light Butts is suitable.

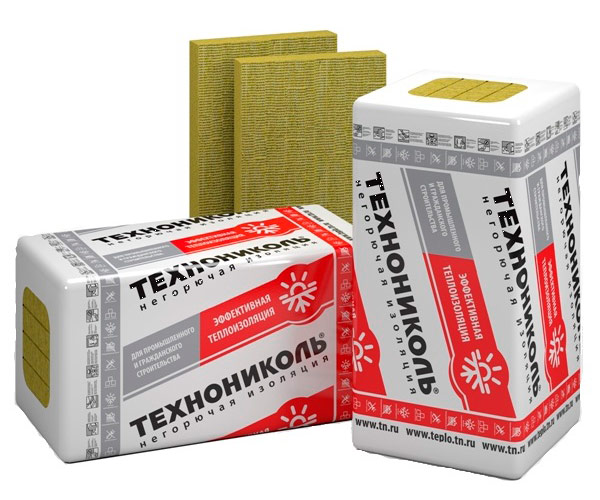

TechnoNICOL

The Russian company TekhnoNIKOL has long entered the international market. It has more than 50 factories in 7 countries of the world, its own scientific and educational centers. The thermal insulation produced by it is a mineral wool insulation, the quality of which corresponds to GOSTs, it is heat-efficient and practical.

Minvata TekhnoNIKOL differs in form stability, excellent noise absorption, incombustibility, hydrophobicity. A wide variety of types (more than 35 plate models) allows you to choose a heat-insulating material for warming a specific building structure.

Types of mineral wool produced: basalt cotton wool.

Release form: plates, there is a unique development of the company - double density plates.

Overview of brands of mineral wool manufactured by TechnoNICOL

- For pitched roofs, different types are used with the name Tekhnoruf: Tekhnoruf Prof, Tekhnoruf V Optima S, Tekhnoruf B 60.

- The flat roof is insulated by Tekhnoruf N Prof Klin (1.7%). A material with a unique shape creates the required technological slope of 1.7 degrees.

- For vertical walls, horizontal or inclined structures, Rocklight is used.

- For attics of horizontal or inclined surfaces use Technolight.

- For heat and sound insulation of floors, Technoflor is suitable.

- Ventilated facades are insulated with plates of Technovent, Technovent Extra, Technoblock.

- For stucco facades use Technofas Decor or Technofas Cottage.

The company annually launches new types of products with improved features.

ISOVER

ISOVER thermal insulation is produced by the largest international industrial company, headquartered in Paris, and representative offices in 67 countries of the world.

Types of mineral wool produced: glass wool and basalt wool.

Release form: plates and rolls.

Overview of the brands of mineral wool manufactured by ISOVER

- ISOVER Frame House is used for insulation of all parts of the frame house without exception: walls, roofs, ceilings, attics, exterior facades, internal wall partitions.

- ISOVER Warm Wall Master is used for indoor and outdoor insulation of wall structures. They are used for siding facades with all kinds of siding, and are installed under the facing brick.

- ISOVER Master of Warm Roofs - slabs designed for sound and heat insulation of pitched roofs, mansard walls.

- ISOVER Facade and ISOVER Facade Master - mats for external insulation with plaster finish.

- ISOVER Venti is a high-quality heat insulator for ventilated facades.

- ISOVER Light is used for soundproofing interior partitions, heat and noise insulation of false ceilings.

- ISOVER Acoustic is specially designed for the effective noise insulation of building structures in private houses and apartments of multi-storey buildings. Sound absorption efficiency is officially confirmed by laboratory test reports.

- ISOVER Optimal is a universal product used for insulation of horizontal ceilings, sloping ramps, vertical walls.

- ISOVER Standard is suitable for pie frame walls, laminated structures, external insulation for siding.

The products are characterized by heat efficiency, excellent sound-absorbing properties, high density - ISOVER mats are installed by surprise without fasteners.

URSA

URSA is a well-known European brand. Currently, the parent company is part of a German concern. The company launched production at 13 plants in 8 countries. Under the URSA brand, high-quality mineral wool insulation based on fiberglass (glass wool is labeled as Ursa GEO) and basalt rocks is produced. The form of production is diverse - hard mats and soft rolls. The purpose of different grades of mineral wool insulation URSA depends on the building structures for which they are intended.

Types of mineral wool produced: glass wool and basalt wool.

Release form: plates and rolls.

Overview of mineral wool brands manufactured by URSA

- Roof. Pitched roofs are insulated with URSA TERRA boards.

- Exterior ventilated facades and walls of frame houses are filled with slabs URSA TERRA 34PN.

- Walls and interior partitions are insulated with mats with soundproofing effect URSA TERRA NOISE PROTECTION or URSA TERRA 36PN.

- Attic, interfloor ceilings, floor logs over a cold basement are insulated with URSA PUREONE 37PN rolls.

- Floors on the ground, on a rigid concrete base, under the floor heating system are thermally insulated with URSA XPS 30, 50 or 100 mm thick boards.

- For foundations, basements, there are URSA XPS mats - they can be laid outside or inside structures.

- Baths, saunas are insulated with URSA TERRA 36PN boards.

- Balconies, loggias are insulated by URSA TERRA 34PN or URSA PUREONE 34PN.

URSA heat-insulating mats and rolls are characterized by durability, trouble-free operation, good heat-preserving properties, and excellent sound-proofing characteristics.