Modern materials for soundproofing walls in an apartment or house

The problem of excess noise in the house is not as harmless as it might seem. With the modern rhythm of life in the city, the additional noise that exceeds the permissible level even by several decibels turns into a threatening factor that interferes with rest, relieve tension and causing nervous exhaustion. The solution to this problem is the most important task of architects and builders. Different types of sound insulation perform their functions differently, but, in one way or another, reduce noise pressure.

Soundproof materials based on both natural and synthetic components have been developed, designed for contact with different wall materials, differ in different density, elasticity, water resistance, resistance to burning and, of course, installation technology. What modern materials exist for soundproofing walls in an apartment or house and how to choose the best view for each specific use case will be discussed in this review.

Content:

Soundproofing materials MaxForte

The Russian manufacturer MaxForte offers a wide selection of innovative soundproof materials developed in collaboration with scientists from the Acoustics Department of the Physics Department of Moscow State University and tested at the Institutes of Building Physics of the Russian Academy of Sciences, NIIIMstroy, and the Vibroacoustic Research Institute. The product range allows you to perform high-quality sound insulation with composite materials, both residential buildings and offices, hotels, shopping centers and industrial workshops.

The main materials of Maxforte:

- ECOplate;

- Standart

- EcoPanel;

- EcoAcoustic;

- Noise Isol.

They differ in the scope and some technical characteristics, but are equally safe in an environmental sense and are allowed without restriction for use in civil and industrial construction.

Maxforte Ecoplate

Designed for soundproofing rooms with a large indicator of sound pressure - cinemas, recording studios, concert halls, home theaters. Even in the rooms adjacent to the indicated or similar rooms, almost no sound is heard - the noise absorption level by the NRC index is only 0.92 units (layer thickness 50 mm, at 100 mm - 0.95 units)

A sound absorber is made of volcanic mineral rocks without the addition of phenols, formaldehyde or other binders with toxic properties. When heated to a high temperature, the material does not emit odors and volatiles that can cause allergic reactions.

ECOplate MaxForte does not burn and does not support combustion, perfectly protects the house from heat loss, resistant to high humidity, is not afraid of rodents, mold and fungal infections. The cost of IVF slabs is approaching a similar soundproofing made of mineral wool, but in many respects it is much ahead of it.

Specifications Maxfort ECOplate:

| Sizes, m | 1X0.6X0.2 - 0.3 |

| Element weight, kg | 7 |

| Plate Volume, m3 | 0,12 |

| The area of plates in the package, m2 | 2,4 |

| Working temperature, 0FROM | — 260 - +900 |

| Shelf life | Is not limited |

Installation of IVF plates is carried out both outside and inside the premises for external decoration with plaster, siding, lining, drywall.

Maxforte Standart

Standart roll material is characterized by low sound permeability and a high level of sound absorption, which determines its use in rooms with high requirements for acoustics - cinemas, concert halls, recording studios, classrooms. When isolating walls and ceilings in apartment buildings, it provides almost complete isolation from street noises and sounds from neighboring apartments.

MaxForte Standart also has a high level of hydro and thermal insulation. Such a combined action, combined with ease of installation, ensures the demand for material in residential and industrial construction at all levels. The material does not burn (group G1) does not emit volatile substances, does not interact with cement, gypsum, lime and other components of building materials.

Standart is made on a rubber basis, its thickness is only 12 mm. Elasticity and lightness make it possible to isolate complex architectural structures as efficiently as possible, without noticeable effect on the internal volume of the room. The material is unique in its own way, it received the patent of the Russian Federation No. 105195 dated January 25, 2011, and no factory in Russia or Europe produces analogues.

Specifications Maxfort Standart

| Sizes, m | 6x1.4x0.012 |

| The area of the roll, m2 | 8,4 |

| Impact Noise Reduction Index, dB | 47 |

| Airborne noise reduction level, dB | 0,8 |

| Sound Absorption Index, αw, MN | 0,45 |

The material is used both indoors and outdoors on walls and ceilings; installation in the system of underfloor heating is allowed.

MaxForte EcoPanel

A complex multi-layer structure, filled inside with dry quartz sand, absorbs the sounds of the entire audible spectrum, including the lowest. The sound insulation index is 48 dB. The heavy construction, due to the sand filler, not only eliminates the possibility of resonance, but also minimizes the reflection of sound waves, which is very important in soundproofing studios or spacious auditoriums and halls.

The panels are designed for soundproofing walls and ceilings, mounting partitions, including mobile ones. Small thickness - only 12 mm provides the same sound insulation as the layer of rolled materials up to 50 - 100 mm. Large intrinsic rigidity simplifies installation. A robust multilayer frame made of cellulose-containing materials and hard lining make ECO panels an independent structural material. Installation technology resembles the installation of drywall.

Specifications EcoPanel MaxForte

| Sheet dimensions, mm | 1200X800X12 |

| Weight kg / m2 | 19,7 |

| Impact Absorption, dB | 33 |

| Airborne noise reduction, dB | 48 |

| Resistance to compression kg / m2 | ≥ 1000 |

EcoPanel MaxForte is used in the form of solid structures for wall and ceiling cladding, installation under floor coverings, as well as in separate fragments - for insulation of speakers, doors, and housings of stationary cars.

MaxFort EcoAcoustic

The material for the manufacture of ECOAcoustic is polyester, a derivative of polyester in the form of fibers. Typically, various resins and synthetic binders are used to join and shape them. But Acoustics uses an innovative technology of sintering threads at high temperature. This allowed to exclude environmentally unsafe substances from the composition, while maintaining the required strength.

Polymer fibers are laid out in a special way, calculated at the Acoustics Department of Moscow State University. The structure of the non-woven canvas resulting from this provides not only high mechanical strength, but also a low transmittance of sound with high noise absorption of the entire audible spectrum.

Polyester in its physicochemical properties is a rather unique material. Is he:

- does not burn,

- does not absorb water

- does not interact with most organic solvents;

- not afraid of biological pests, mold and fungus;

- excellent heat insulator.

Unlike glass wool and some other heat and sound insulators, the material does not create discomfort during installation - the fibers hold tightly in the bulk of the material and when working with it there is no need to use protective devices and workwear. You can cut the canvas with ordinary scissors.

Specifications MaxFort EcoAcoustic

| Sizes, mm | 1200X600X50 |

| Density, kg / m3 | 1000 |

| Sheet / packaging area, m2 | 0,72/2,88 |

| Weight of sheet / package, kg | 0,75/3 |

| The coefficient of thermal conductivity, W / (m x K) | 0,032 |

It is used in residential buildings and offices, frame structures and metal structures in a vertical and horizontal position.

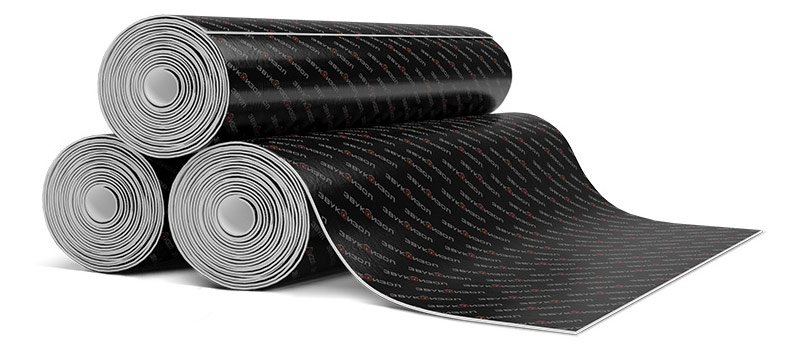

Max Forte Noise Isol

Intended material for soundproofing the floor. It features increased flexibility and elasticity combined with mechanical strength. It is made in the form of rolls and laid under parquet, plank floor, laminate, ceramic tile. Excellent waterproofing agent. It can be installed on the first floors of unheated rooms - ShumoIzol is not afraid of low temperatures, maintaining its properties and integrity up to 25 degrees below zero.

It is produced in the form of a two-layer material with a non-woven polyester coating and a bitumen base layer. Depending on the type of flooring, it is laid with one or the other side up. Before starting installation, you must carefully study the instructions. Butt rolls are connected, the seams are insulated with mounting tape or one-component liquid rubber.

Technical specifications MaxForte ShumoIzol

| Sizes of a roll, m | 10X1X0.05 |

| Area, m2 | 10 |

| Weight, kg | 19 |

| Temperature range of use, 0C | — 25…+ 85 |

| Noise reduction index, dB | 27 |

It is used for noise and vibration isolation in residential premises, production shops, energy generating enterprises. There are no restrictions on the use of environmental indicators.

Soundproofing materials ThermoZvukoizol

Soundproofing materials from the Russian company RUS KORDA LLC belong to the multilayer family. They consist of an external coating - durable spunbond fabric, and the actual sound-absorbing soundproof layer - fiberglass filler.

The following varieties of material:

- ThermoSoundInsol 10 mm

- ThermoSoundInsol 14 mm

- ThermoSoundIsol Forte

- Thermo Sound Insulation Tape

This is a fairly flexible material - it can be rolled both on flat surfaces, and around beams, beams and other structural elements. It is installed both in horizontal and in vertical position, from above it requires mechanical protection with finishing materials. Suitable for siding, lining, particleboard, fiberboard, CSL, dry plaster and drywall. On the floor under the screed is placed under the waterproofing film.

It has ThermoZvukoIzol excellent vapor permeability, non-combustible, it stores heat well in the house and can be used without additional thermal insulation of walls and ceilings. Like the soundproofing of walls in an apartment, modern materials from CORDA practically have no competitors.

It is produced in rolls of a standard size - 10000 x 1500 x 10-14 mm. There are no other forms of release, if the store offers material in the form of mats, pillows or other form factors, then this means a fake, which, alas, there are quite a lot on the market. This indicates not only the desire of counterfeiters to make money fraudulently, but also the popularity of the material. Non-demanding products are not faked.

The same form of release also applies to the ThermoZvukoIzol Forte material, which is characterized by improved characteristics. Like the usual ThermoZvukoizol, it is used on walls, ceilings, floors. You can also buy a soundproof tape with dimensions of 1000 x 130 x 14 mm for insulation of pipelines and structural elements.

The working temperature of the material is in the range of -100 ° C to + 140 ° C, the thermal conductivity in the range “A” is 0.034 (W / m.K), and the water absorption is up to 49.5%. It is produced in thicknesses of 10 and 14 mm, modification of Forte - 12 mm.

Technical Specifications ThermoSoundIsol

| Title | Sound absorption, dB | Impact Noise Reduction, Multiplicity | Vibration reduction, multiplicity |

| ThermoSoundInsol 10 mm | 28 | 4 | 12 |

| ThermoSoundInsol 14 mm | 33 | 4 | 13 |

| ThermoSoundIsol Forte | 44 | 13 | 13 |

| Thermo Sound Insulation Tape | 17 – 90% | 15 | 15 |

The material ThermoZvukoIzol is used in all modifications at civil and industrial construction facilities of various levels - from cottages and summer cottages, to large production facilities, residential complexes and shopping and entertainment centers. Manufacturability, fire resistance, light weight and low thickness allow it to be used with virtually no restrictions in rooms with a dry and normal microclimate.

Soundproofing materials SoundIsol

Universal rolled material for noise insulation and insulation of buildings of various categories, also has a significant level of waterproofing. There are two types of material: Soundproof and - Soundproof - M.

The material is a multilayer coating consisting of:

- polymer modified bitumen;

- foamed polyethylene;

- protective polymer film;

- aluminum foil (Soundproof M).

Zvukoizol is intended for insulation of floors, including underfloor heating, installation under a floating screed, in attics and under a soft roof. Ecological safety of the material allows its use in children's, public and medical institutions without restrictions. It contains no substances that can emit odors or toxic components when heated, and also cause allergic reactions.

Soundproof rolls are laid directly on the base with the bitumen part up, the joints are sealed with a special self-adhesive tape on a bitumen basis, completely sealing the contact area. The material is perfectly cut to size with ordinary scissors or a knife. The low level of moisture absorption (less than 1%) allows you to use SoundIsol in basements, basements, for hydro and thermal insulation of basements.

Specifications SoundIsol

| Sizes of a roll, mm | 6,000 -20,000x1000x4-5.3 |

| Shock absorption level, dB | 25 - 28 |

| Weight, kg | 9,6 – 28,8 |

| Area of coverage, m2 | 6 - 20 |

| Compliance with GOST | 16297-80, 27296-87 |

It is used under screed in all types of buildings of categories "A", "B" and "C". Soundproof M is installed in underfloor heating systems with electric or water heating.

Softboard (soft board)

The material created using innovative technology consists of wood fibers, mainly conifers. Wood is crushed and pressed in a certain way, resulting in a loose, but sufficiently strong structure, somewhat similar in properties to a cork. Weak bonds between the fibers and the presence of air voids (up to 70%) determine low thermal conductivity (not more than 0.042 W / m * K), high heat capacity ((2.3 kJ / kg * K) and active noise absorption.

The strength and elasticity of the material allows it to be used in the decoration of walls, floors and ceilings, as part of the multilayer construction of heat and sound insulation in frame and stone houses. It is usually mounted on the inside of the room. High vapor permeability allows it to be used in living rooms, kitchens, bathrooms, baths, saunas. The material does not retain moisture, which excludes the appearance of conditions for the growth of mold or fungal infections.

As an active soundproofing material, soft boards are used in residential and public buildings of all kinds. It not only has low conductivity of shock and airborne noise, but also actively absorbs the sounds of the entire frequency range and vibration from working machines and equipment.

Set SoftBoard for exterior decoration. It can be:

- paint with acrylic, alkyd and oil paints;

- plaster with regular and decorative plasters;

- cover with lining or siding;

- wallpapering.

The warranty period for maintaining mechanical integrity and basic properties exceeds 10 years. In reality, the service life is much longer. The pressing process does not use synthetic resins or other dangerous binders capable of releasing volatile toxins or allergens. SoftBord is not inferior to ordinary wood in terms of environmental friendliness.

SoftBoard Specifications

| Sizes, mm | 1220x2440x40-120 |

| Thermal conductivity, W / m * K | 0,042 |

| Heat capacity, kJ / kg * K | 2,3 |

| Sound absorption coefficient,% | 80 |

| Sound reduction level, dB | Up to 35 |

| Water absorption,% | 4 - 6 |

| Operating temperature range, 0FROM | — 50…+140 |

The density of the plate in different versions is different. Range - 180 - 330 kg / m3that determines different mechanical properties and weight. Typically, slabs of lower density are laid on horizontal surfaces, larger - on vertical ones. You can cut the material to size with a regular or band saw, jigsaw.

Tecsound

Sound insulation membranes of the Spanish company Texsa are used as an independent soundproofing layer or in combination with other soft heaters and sound insulators as part of multilayer coatings. Membrane thickness of only 3.7 mm slightly affects the size of the soundproof layer, but can reduce the level of external noise by more than 25 - 28 dB. When there is a real possibility of shock noise, Tecsound is used in combination with vibration-proof materials, for example, Schumanet, ThermoZvukoizol, Polifoam and others with similar properties.

Tecsound has a high density, as a result of which it is quite resilient and can be used for soundproofing a floor under a screed or a solid base made of plywood or chipboard. At temperature extremes, the material deforms slightly and is not able to affect the integrity of the protective thermal insulation layer, antiseptic properties and low absorption of water and steam allows it to be used in rooms of high humidity.

In the firefight, it is absolutely safe, has antiseptic properties and is not damaged by rot, mold and other biological factors. The material is very plastic and is able to stretch significantly without tearing and cracking during thermal deformations or mechanical movements of the structure. By its mechanical properties, it is very similar to sheet lead, but it is absolutely non-toxic and can be used indoors without restrictions.

Tecsound Specifications

| Sizes of a roll, mm | 5 000x 1220x3.7 |

| Weight, kg | 42 |

| Soundproofing index Rw, dB | 28 |

| Sound absorption level, dB | 22 |

| Combustibility class | G2 |

As a membrane material in multilayer sound and thermal insulation systems, Tecsound is used in all types of buildings, on ceilings, floors, walls and ceilings. It does not react with the components of mortars, goes well with mineral and polymer insulation of all kinds.

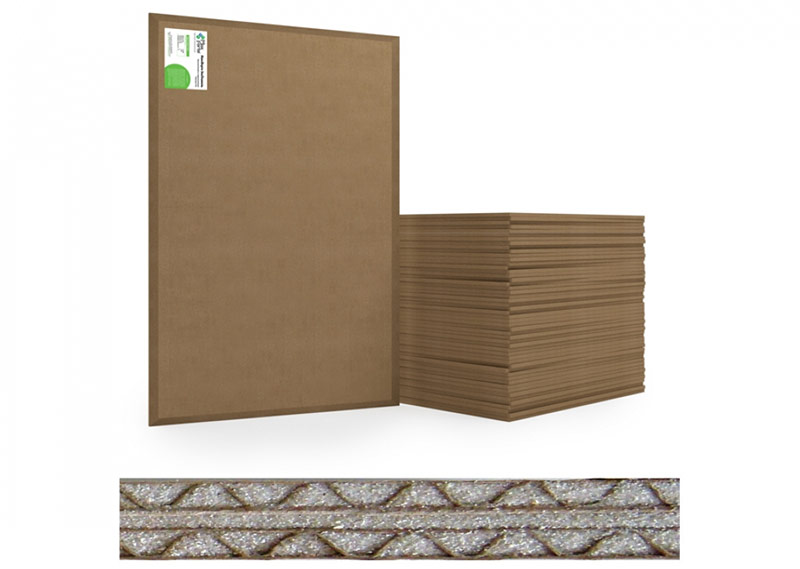

Soundproofing PhoneStar panels (Fonstar)

PhoneStar brand sheet material for protection against shock, airborne noise and vibration is produced both in Germany and in Russia, sweat by the technical control of Wolf Bavaria, in the laboratories of which it was created. It is a rigid panel - a frame of pressed corrugated cardboard filled with quartz sand or special granular filler.

Cardboard provides proper rigidity in vertical and horizontal position, and loose filler dampens sound vibrations of any length. When installing sound insulation, it is necessary to prepare a wooden or metal crate, to which the panels are attached with self-tapping screws with a wide hat. At least 15 mounting points are required per panel for horizontal installation on the ceiling.

When installing on the floor, hardware is usually not used. On the wall, the number of fasteners depends on the type of external finish - there can be less of them for wallpaper or putty than for the ceiling, more for plaster. Joints are sealed with special WOLF TAPE tape or construction tape. If the panels have to be cut to size, then the ends should also be sealed with tape to prevent the filler from spilling out.

Specifications Fonstar

| Sheet dimensions, mm | 1195x795x12 |

| Weight, kg | 17,4 |

| Area, m2 | 0,95 |

| Noise absorption index Rw, dB | 36 |

| Impact noise reduction,% | 75 |

Soundproof panels are used at all industrial and residential construction sites, both as an independent soundproofing material, and as part of multilayer structures, in combination with soft mineral sound-absorbing materials, gypsum plaster, membranes, etc. Exterior finish is made directly on the panel with all types of plasters and putties, wallpaper, paints, siding or lining. Designed for indoor use.

Soundproofing Knauf

Sound insulation materials of the German KNAUF concern, like all building materials of this brand, belong to the professional class of products and are distinguished by unsurpassed quality and unique parameters. The company offers modern materials for soundproofing walls in an apartment or house, which differ in simplicity of installation and durability of operation.

New AcousticsKNAUF

There are several types of soundproofing materials in the KNAUF product range, one of the most popular of which is New AkustiKNAUF.

This is an innovative material that surpasses those used previously in terms of stiffness, elasticity and the ability to restore shape after mechanical deformation. Elasticity allows the material to densely fill the frame openings and hold there under vibration or shock loads on walls and partitions during installation and further operation.

The main material is mineral fibers bonded with environmentally friendly binders using ECOSE technology. Formaldehyde and phenols in the production of AcoustiKNAUF New are not used. In terms of environmental performance, a sound absorber is approved without restrictions for use in residential buildings and apartments, children's and medical institutions, and public places. It does not dust, does not emit odors and toxic substances in any mode of operation, non-allergenic.

Technical characteristics New AkustiKNAUF

| Sheet dimensions, mm | 2130x610x50 |

| Sheet area, m2 | 0,75 |

| Combustibility group | NG |

| Noise reduction level, dB | Up to 57 |

| Density, kg / m3 | 15,5 |

The material is used to create a soundproof gasket in a complex multilayer finish in combination with GKL or GVL. It is installed during interior decoration of walls, ceilings, partitions. Can be installed in structures hollow, under a rigid base on the frame.

KNAUF Insulation Acoustic Partition

Another concern of the concern from Germany is no less in demand - KNAUF Insulation Acoustic Partition. Created on the basis of mineral wool, it performs both soundproofing and heat-insulating functions. It is made in the form of plates or mats, characterized by a high level of elasticity. It is used in dry wall and ceiling systems in residential and industrial construction. It features active sound absorption and vibration protection.

In the sound range of 125 - 4000 Hz, the noise absorption coefficient is 0.56 - 1, which reduces the overall sound background by 30 - 40 dB. Thin fibers (not more than 3-5 microns) in the form of long filaments (up to 150 mm) provide active resistance to the propagation of sound waves and absorb their energy at all frequencies. Large sizes of plates and rolls allow minimizing the number of joints, which positively affects the level of sound insulation and thermal protection.

Specifications KNAUF Insulation Acoustic Partition

| Plate dimensions, mm | 1250x610x50 |

| Sizes of a roll, mm | 7500x610x50 |

| Sound absorption coefficient (50 mm) | 0,25 – 0,94 |

| Noise reduction level, dB | 30 - 40 |

| Plate Area, m2 | 0,76 |

| Mat area, m2 | 4,575 |

Knauf Insulation is used in frame systems of walls and partitions in all types of residential and industrial construction, it is actively used in systems of suspended ceilings and floors with any kind of coverings.

Soundproofing TechnoNIKOL

The Technonikol company is a well-known manufacturer of roofing, soundproofing and heat-protective materials in the construction world. The company's products are in constant demand due to high quality and a wide range that meets any builder's needs.

Tekhnoelast ACOUSTIC

Sound insulation material for floors is used to protect against impact noise propagating through structural elements of the building frame. It is produced in two types - Acoustic Super A350 and Acoustic S B350.

The first is fiberglass with a polymer-bitumen layer applied and a thermal bonding method glued to it with high sound-proofing properties. The material is reinforced with a metallized film deposited on the opposite plane of the soundproof layer. The material performs several functions - soundproofing, waterproofing and thermal insulation of ceilings.

Acoustic S B350 is a self-adhesive polyester metallized film with a bitumen layer and a soundproofing sheet applied to it. Designed for installation under a cement screed. Mostly Tekhnoelast AKUSTIK is installed in the system of floors, including those heated by electricity or a liquid heat carrier, but it is also actively used when installing partitions and protecting walls from the inside.

Technical characteristics of Acoustics Super A350 / S B350

| Sizes, mm | 10000x1000 |

| Density, kg / m2 | 2,2/0,7 |

| Noise reduction index, dB | 27/23 |

| Water resistant% | 100 |

| Compliance | SNiP 23-03-2003, SP 51.13330.2011 |

The material is used in the construction of multi-storey buildings for various purposes. There are no restrictions on environmental indicators.

TECHNOLIGHT

No less popular material for sound insulation from TechnoNIKOL. It is used in non-loaded systems of insulation and sound insulation in the decoration of any type of building. It is based on mineral wool treated with a binder with a minimum phenol content. It is made in the form of plates with a sufficient level of elasticity, ensuring shape preservation and reliable retention in the frame openings.

It can also be used in systems of ventilated facades as a wall layer, protected from the outside by more durable material. When installed vertically in a rigid frame, it does not require additional fasteners. It is produced in two types - Extra and Optima, which differ in some basic parameters.

Technical characteristics of Technolight "Extra" / "Optima"

| Sizes, mm | 1200x600x40-200 |

| Density, kg / m3 | 30-38 / 34-42 |

| flammability | NG / NG |

| Water absorption,% | 1,5 / 1,5 |

| Sound absorption coefficient (100 mm) | 0,55-0,96 |

The use of Technolight is practically unlimited in all types of buildings for interior decoration of walls, floors and floors. The material is chemically resistant to mortars and paints, easy to cut, not damaged by mold, fungus and rodents, does not emit toxic gases, does not dust. At high or low temperature does not deform.

Soundproof Panel System (ZIPS)

ZIPS Vector

The purpose of the "Vector" panel systems is to improve the soundproofing characteristics of existing walls. The panel system is a complex of sandwich panels and plasterboard trim up to 12.5 mm thick. The sandwich panel itself consists of external gypsum plasterboard walls and a fiberglass layer. For mounting the system does not require installation of the frame - the rigidity of the panels makes them self-supporting. The panels, in addition, are equipped with a tongue-and-groove system of locks that facilitate installation and increase the strength of the structure.

Specifications ZIPS Vector

| Sizes, mm | 1500х500х40 (53) |

| Panel weight, kg | 18,5 |

| Sound absorption index, dB | 18 - 20 |

| Combustibility group | G1 |

| External noise reduction level, dB | 6 - 18 |

Usually they are used for repairs, but there are no barriers for their use in new construction as part of a multilayer finish. As an effective soundproofing of walls in an apartment, modern materials for wallpaper, painting, decorative plasters, panels are used in residential and office premises, where the expected sound pressure does not go beyond the limits of household noise. The maximum effect of the use of SPIPS is achieved only with strict adherence to the installation technology.

ZIPS Module

Like the previous version, the “Module” system consists of two parts - an internal sandwich panel and an external gypsum board lining.Internal insulation is a layered structure of gypsum plasterboard frame and mineral fiber glued from it from basalt rocks. This design provides the required rigidity, fire safety and environmental friendliness. No additional frames need to be assembled for the installation of ZIPS - the panels are attached directly to the wall with dowels or self-tapping screws (ideally, special vibration-damping mounting units).

The tongue-and-groove system of locks provides tightness and durability of a design. Exterior finish of GKL with a thickness of 12.5 mm allows you to stick wallpaper, putty, paint, apply decorative plaster.

Specifications ZIPS Module

| Panel dimensions, mm | 1500х500х70 (83) |

| Element weight, kg | 19 |

| Sound insulation level, dB | 12 -20 |

| Index Rw, dB | 12- 14 |

| Fire resistance | G1 |

The system is designed for soundproofing walls in rooms with an average sound pressure level - cafes, restaurants, shops, production halls and workshops, where the noise level can reach 100 dB. It is only necessary to evaluate the effectiveness level of SPIPS module in combination with the properties of wall material. On brick, concrete, cellular and ordinary concrete, it can vary significantly.

ZIPS Cinema

The most powerful of ZIPS - "Cinema" is designed to protect against noise from entering outside from rooms with a significant level of sound generation - concert halls, industrial halls, machine rooms, boiler houses and pumping stations. The system actively reduces the intensity of sound vibrations, starting from 80 Hz of the audible range.

Structurally, “Cinema” is similar to the “Module” system, only the layer of mineral fiber is much larger - up to 110 mm. This significantly increases the level of sound absorption, without compromising the overall mechanical strength.

Specifications ZIPS Cinema

| Sizes, mm | 1500х500Х120 (133) |

| Noise reduction level, dB | 10 - 24 |

| Index Rw, dB | 16 - 18 |

| Element weight, kg | 21 |

| Weight 1 m2 | 39,5 |

The system is installed on brick, stone, concrete and plasterboard walls and partitions in rooms and halls for any purpose. The absence of toxic substances and synthetic resins in the composition allows the use of panels in residential and public buildings without environmental safety restrictions.

The choice of the best material for sound absorption and soundproofing of an apartment depends on the architectural features of the house - layout, room configuration, wall material, exterior decoration option.

Ideally, specialists should be involved in the development of a sound insulation project - rarely a soundproof layer performs only one function, much more often it is only a component of an integrated system designed to protect a house from excessive noise, heat loss and moisture penetration into a wall array.