Screw piles: characteristics, advantages and disadvantages

The foundation of the house is one of the most complex and expensive elements of its design. At the same time, the process of its creation is very long - in most cases this is a limiting stage of construction. Unfortunately, it is not uncommon for unscrupulous developers to consciously violate technologies and norms in order to complete the foundation as soon as possible and proceed to the next stages of work. Often, the customers themselves are pushing them to do this, and it seems to them that nothing has been happening on the construction site for too long. Excessive rush at this stage leads to the fact that soon the residents of the new house have problems - the foundation sags, and, as a result of this, the whole structure begins to slowly collapse.

Is there a middle ground here? Is it possible to quickly mount a strong and reliable foundation? It turns out, perhaps. Screw piles come to the rescue in this case. Creating a foundation on screw piles requires not just one or two months, but just a couple of days.

Why are such piles still not used everywhere? Why don't new homes grow as fast as mushrooms after rain? To answer these questions, you need to know not only the pros, but also the disadvantages of screw piles for the foundation, to have an idea of what limitations there are to their application. Remember that the foundation is a very responsible matter, and when choosing a design solution you should rely primarily on your own knowledge, and not on the advertising assurances of manufacturers, the promises of builders or examples of neighbors and acquaintances.

Content:

The history of the appearance of screw piles

The history of screw piles dates back nearly two centuries. A coup in the field of pile foundation construction was made by the talented Irish engineer Alexander Mitchell. In 1833, he patented the “Mitchell Screw Piles”, which could be installed in moving soils, such as the sandy bottom of a pond or silt.

The first major structure erected on such stilts was the Maplin Sand lighthouse, built at the mouth of the Thames already in 1838. Its foundation was nine piles with screw tips 120 cm in diameter, twisted into the ground to a depth of about 7 meters. In the following years, several more lighthouses were built under the direction of Mitchell throughout England. Some of them have remained unchanged to this day.

More than 150 lighthouses in North America, a breakwater in Portland, an overpass and bridges in Bombay, a railway in Baroda, a pier in Madras and many other important objects were built in the mid-19th century using Mitchell piles.

In Russia, screw piles were found out only in the second half of the 19th century. Russian engineers quickly appreciated all the advantages of this invention, especially when working in the permafrost of the northern regions of the country or weak, flooded soils of coastal areas. Very soon, screw piles began to be widely used in the construction of engineering structures for military purposes (the frame-screw support for high-speed construction of foundations of collapsible bridges is used by our military until now), and later in civil engineering.

Steel screw piles are actively used around the world today. They resort to their help where a high speed of foundation construction is needed: when installing various types of supports, deploying pumping and drilling stations, laying pipelines, building temporary camps for workers, etc.These products are in greatest demand among oil and gas companies, military and industrial builders, and companies performing restoration work. Construction organizations involved in the construction of residential buildings are present on this list, but far from leading positions. Of course, the foundations on screw piles for residential buildings are erected, but in most cases we are talking about building in hard-to-reach areas or areas with difficult soil, repairing the problematic foundations of old residential buildings, and fixing buildings on the slopes.

Design and characteristics of screw piles

What are screw piles that so quickly gained popularity among builders around the world? What varieties of them exist? What characteristics of screw piles should I pay attention to first of all?

A screw pile consists of a trunk and a blade located at its end. Thanks to the latter, this type of pile is buried in the ground by screwing in, not clogging.

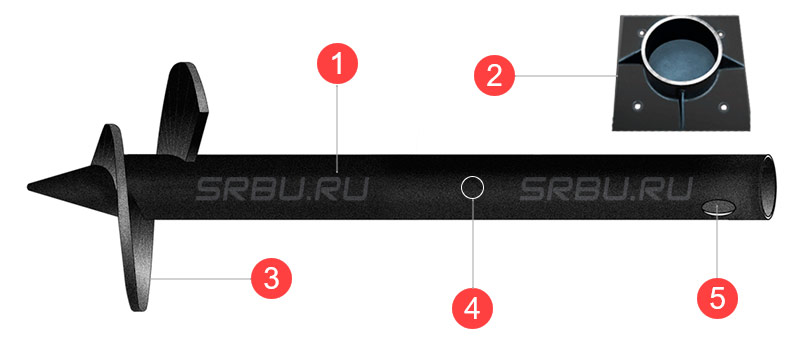

1. The pipe. 2. The head that is attached to the top of the pile. 3. Spiral-shaped blade. 4. Anticorrosion coating. 5. Technological hole for setting the rod.

There are several varieties of steel screw piles. The choice in favor of a particular type is based on an analysis of the characteristics of the soil in this area and the estimated load on the foundation. Often, even at one site, different types of piles are used, which allows you to evenly distribute the load.

Screw Tip Type

The tips of screw piles, serving to facilitate their immersion in the ground, can be welded or cast.

Screw pile with welded tip.

Cast tips are much more expensive, and their use is justified only in the case of work with especially dense soils, including permafrost, and also containing large inclusions of natural or technogenic origin. Durable cast tip when screwing piles easily destroys obstacles in its path and does not deform at the same time.

Cast pile screw pile.

Number of blades

By the number of blades, screw piles are divided into single and multi-blade (the number of blades on one shaft in some cases can reach six pieces). The former are intended exclusively for dense soils with low mobility.

Single blade screw pile.

The second are more universal, although their main purpose is soft soils with low bearing capacity, since multi-blade piles are more resistant to various types of loads - pulling or, conversely, pressing, and horizontal. The maximum efficiency of multi-blade screw piles can be achieved by correctly selecting the number of blades, the optimal distance between them, their pitch and angle.

Two-bladed screw pile.

Blade size

By the size of the blades, screw piles are divided into broad-bladed (the diameter of the blades is at least one and a half times the diameter of the trunk) and narrow-bladed. Thanks to the increased bearing area, broad-pile piles are very effective in soft soils.

Broad-bladed screw piles.

Narrow-bladed ones have their own specialization - especially dense or very frozen ground (it is impossible to “screw” a broad-bladed pile into such soil due to the greatly increased risk of breaking or deforming the blades). The diameter of the blades of a screw pile according to the international standard ICC AC358 (Helical Foundation Acceptance Criteria) can vary from 200 to 350 mm.

Narrow-bladed screw piles.

The thickness of the metal of a screw pile

The most important structural characteristic of a screw pile is the thickness of the metal from which the walls of its trunk are made. The calculation of the required thickness is done based on not only the estimated load on the pile, but also the conditions of its operation. The fact is that reducing the wall thickness of the pile due to corrosion processes ultimately leads to a reduction in its service life.According to the aforementioned ICC AC358 standard, the minimum wall thickness of the pile shaft should be 8 mm in neutral soil and 9.5 mm in soil with increased chemical activity.

Domestic engineers, of course, also realized the importance of such a parameter as the thickness of the metal used to make screw piles. The guide “Piles and pile foundations”, published in the USSR in 1977, stated that the pile shaft should be made of a seamless pipe produced by hot rolling with a wall thickness of at least 10-14 mm. However, in the modern Russian construction standard SP 24.13330.2011 “Pile foundations”, such a parameter as the wall thickness of the shaft of a screw pile is not considered at all and is not standardized.

We will not be making assumptions about why this happened, the consequence is important. Many domestic manufacturers take advantage of the lack of strict requirements for the construction of steel piles in Russian standards and consciously ignore international standards. The desire to maximize profits leads to a loss of quality.

Most screw piles produced in our country have a wall thickness of no more than 3-4 mm. At the same time, they are made from welded pipes with reduced corrosion resistance. And the quality of the protective anticorrosive coating, as a rule, wishes for the best: often it “spills” already during the transportation of piles.

Of course, in Russia they are able to produce (and not only know how, but also produce!) Piles whose quality meets all the requirements of the international standard ICC AC358. However, due to their high cost, in most cases they cannot withstand competition with conventional reinforced concrete piles installed in a pre-drilled well.

The thickness of the metal not only of the pile shaft, but also of its blades should be taken into account. When constructing temporary or light objects, it is permissible to use piles with blades thinner than 5 mm. When erecting large structures designed for long-term operation, the international standard recommends the use of piles with a blade thickness of 9.5-12.5 mm.

Protective anticorrosion coating

To reduce the influence of corrosion processes on the strength characteristics of steel piles installed in aggressive soil, not only increase the thickness of its walls, but also apply an additional protective coating. The most commonly used methods of anticorrosion protection of steel piles are galvanizing and applying a special polymer (polyurethane, epoxy, etc.) coating. According to ICC AC358, the thickness of the protective polymer layer must be at least 400 microns.

Advantages of the foundation on screw piles

Installation speed

High installation speed is perhaps the most important advantage of screw piles, because in the construction business they value time like nothing else. The screw pile is ready for use immediately after installation. Even concreting the internal clearance of the pile shaft does not lead to a downtime at the construction site: there is no need to wait for concrete to gain grade strength, since the load on the pile is primarily perceived by its steel shell.

Low noise when installing the foundation

Low noise during installation is the main advantage of screw piles over driven ones. The process of driving the latter into the ground is accompanied not only by noise, but also by vibration. Vibration effects on the ground can harm various structures located in the immediate vicinity of the work site.

Low price

The low cost of the foundation on screw piles in comparison with the cost of all kinds of reinforced concrete foundations is achieved primarily due to a significant reduction in the volume of land work.

The ability to withstand various pulling loads

This ability is due to the presence of blades in screw piles.Thanks to its blades, these piles can be installed on uneven platforms (which means that they are perfectly suitable for buildings located on slopes) and at any angle to the vertical.

No need to get a large amount of soil

A small amount of soil displaced during the installation of screw piles allows work to be carried out close to existing buildings.

They can be used in various conditions.

The weather-climatic simplicity of screw piles is expressed in the fact that they can be operated in a fairly wide temperature range, are not afraid of rising groundwater and swelling of the soil, and therefore do not require mandatory drainage of the construction site.

Reusable

One of the applications of screw piles is the construction of temporary structures. After such a building has completed its functions and has been dismantled, screw piles can be removed from the ground and reused if necessary.

It is worth noting that only industrially produced screw piles, the quality of which complies with the International Construction Standard ICC AC358 Helical Foundation Acceptance Criteria, have all these advantages.

Disadvantages of the foundation on screw piles

The use of screw piles has a number of limitations, which many manufacturers, unfortunately, try to keep silent. In conditions when the companies involved in the installation of foundations easily go to the violation of technological standards, you, as a customer, need to have at least a general idea of in which cases it is undesirable or completely unacceptable to use screw piles.

Inability to use in areas with seismic activity

The construction of buildings on the foundations of screw piles is allowed only in areas with no or, in the limit, with moderate seismic activity.

Inability to use in soils causing rapid metal corrosion

Steel screw piles should not be used in soils with an electrical resistance of less than 10 Ohm * m, in soils with a pH of less than 5.5, and also in soils with a high content of organic compounds. The reason for these limitations is the high rate of electrochemical corrosion of steel under these conditions. The responsible developer, who is not indifferent to the longevity of the construction being built, before deciding on the use of steel screw piles, is simply obliged to determine all the necessary soil characteristics at this construction site. If it is not possible to determine the aggressiveness of the soil, you must adhere to the requirements adopted for piles installed in soils with very high corrosion activity.

It is not allowed to penetrate screw piles into rocky soil.

This category of soils includes slag dumps and landfills for construction waste. Any solid inclusions can damage the blades or even the shaft of the screw pile during its installation.

It is recommended to avoid using screw piles on soils that do not provide sufficient lateral support.

These include, for example, peat, loose silty sands, etc. If the need to install such piles in a fluid soil still exists, it is necessary either to reliably relate them to each other or to substantially deepen. In accordance with the requirements of the ICC AC358 standard, a screw pile in solid soils must be buried at least 1.5 m, in soft soils - at least 3 m.

We give an example: the installation of a screw pile 2.5 m long in the area where a peat layer lies at a depth of 2 m is unacceptable, since in this case the pile will be deprived of the necessary lateral support of the soil.

Factors Affecting the Durability of Screw Piles

Advertising assures that the foundation on screw piles can last at least a century. Is this really so, or is it just another marketing ploy? Practice shows that this is quite possible, because some of the lighthouses erected under Mitchell still stand.However, we are more interested in the fate of not a lighthouse in distant Europe, but of a small country house somewhere in the suburbs, in the Urals or on the banks of the Yenisei. How long will he stay, being erected on the foundation of screw piles made not somewhere and once, but here and now?

Based on experimental data, the service lives of steel screw piles in soils with different electrical resistance were estimated. According to these estimates, in soil with low corrosion activity (for example, dry shale or dry sand), piles of non-galvanized metal will last at least 300 years, and from metal with a protective coating - 800 years or more. Impressive, isn't it? However, this is a soil ideal in terms of the ability (or rather, the inability) to cause corrosion of the metal.

For comparison, consider another limiting option. In soils with very high corrosivity (marine soil, silt, wet clay, peat), the average predicted service life of a steel screw pile is only 30 years (if the pile is made of galvanized metal, this figure will increase to 70-75 years).

One important caveat should be made. During all these calculations, it was assumed that the pile was produced in accordance with the ICC AC358 standard used in the West, i.e. the thickness of the walls of its trunk is 8 mm. But it is almost impossible to find screw piles of hot-rolled steel pipes with such a wall thickness on the Russian market. How long will the “standard” of domestic production last in an aggressive environment, i.e. a pile made of a welded pipe with a wall thickness of 3-4 mm is unknown to anyone, but is clearly substantially less than 30 (75) years.

From the foregoing, it follows that the 100 years of foundation service on screw piles promised in advertising are nothing more than empty words. Piles can last much longer and significantly less - it all depends on the quality of the products and the operating conditions, which is not mentioned in the advertisement.

In general, the life of screw piles depends on three main parameters:

- the thickness of the steel used to make the shaft and the blades of the pile,

- the thickness and quality of the protective anti-corrosion coating,

- soil chemical activity in this area.

Without knowing these characteristics of piles and operating conditions, one cannot even make assumptions about how long they will last.

The practice of scalding screw piles with bundles of metal channels or corners, widespread among our builders, contributes to a decrease in the service life of screw piles. Of course, the arrangement of such bundles between piles is justified when installing the foundation in the ground with weak lateral support. However, the connection of steel piles with bridges of conductive material leads to an acceleration of electrochemical corrosion of the metal.

In order to avoid the occurrence of stray currents, contributing to the acceleration of corrosion processes, steel piles should not have galvanic connection with each other, as well as with other building elements made of steel. To connect the piles into a single system, you should use a wooden strapping or a metal strapping, the elements of which are connected to the piles by means of clamps isolated from the piles with dielectric material.

That is actually all that we wanted to tell you about today. Now you know all the pros and cons of screw piles and, we hope, understood the main idea that we tried to convey to you. Screw piles are an excellent choice for creating a foundation, but they can not be used always and not everywhere. Only a professional can determine the permissibility of using screw piles in each case. Believe me, the cost of attracting a specialist is incommensurably lower than the cost of eliminating errors made during the design and construction of the foundation.