Ondulin or corrugated board - which is better, comparison of materials

Decking and ondulin - the materials are very different. Perhaps they are similar only in one thing - both are highly competitive in the building materials market. And this means that everyone has a sufficient number of advantages, each worthy of being used by you when building a house.

There is only one way to determine which is better - ondulin or professional sheet. We will compare these roofing materials in various ways. Perhaps some of the factors will be more significant for you than others, and then the scales of doubt will shift in one direction or another.

Content:

- What are ondulin and corrugated board

- Easy installation

- Strength and other physical and mechanical characteristics

- Material weight

- Longevity and service life

- Fire safety

- Sound absorption

- Snow retention

- Preservation of appearance during operation

- Material cost

- The final comparison of ondulin and corrugated board

What are ondulin and corrugated board

Ondulin is often called a euro-slate, since its sheets, like that of asbestos slate, have a wavy profile. It can be distinguished from slate and other roofing materials by several standard colors, a rough surface and a 2-meter-long sheet.

The basis of the material is cellulose fibers compressed at a temperature of about 120ºC. The formed sheets are painted and impregnated with a bitumen-polymer mixture. Bitumen impregnation ensures the waterproofness of the material, without which it could not be used for roofing.

The geometric parameters of the ondulin sheets are standardized. Regardless of the manufacturer, the sheet has a size of 2x0.96 m with a wave height of 36 mm and a material thickness of 3 mm.

Profiled steel sheets - universal material. The scope of its application is much wider than that of ondulin: it is used not only for roofing, but also for the construction of fences, wall cladding of industrial premises and garages, etc. In this regard, there are several varieties of this material.

Each type is indicated by its letter:

- H (carrier);

- C (wall);

- NS (non-existent wall).

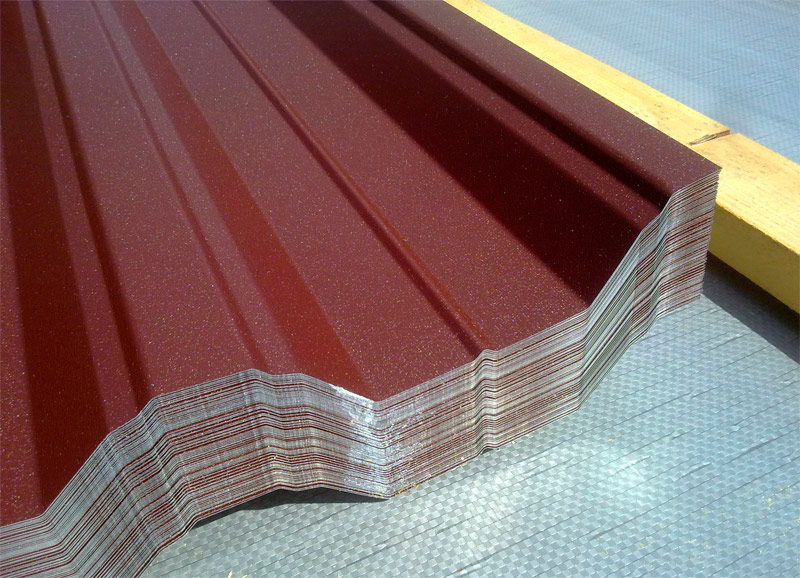

In accordance with European and Russian standards, when covering the roof of capital buildings, it is allowed to use profiled metal sheets with a trapezoidal wave, the height of which is not less than 20 mm. The thickness of the material should not be less than 0.4 mm. These requirements are met by grade H decking (some manufacturers use the abbreviation NK - roofing). Further, we will focus on the supporting roofing decking, we will omit all other varieties of material from consideration.

Roofing corrugated board is a steel sheet, which is given a wavy shape by cold rolling. The thickness of the material can vary from 0.4 to 0.8 mm, and the wave height from 20 to 75 mm (less often up to 115 mm). The sizes of sheets of corrugated board are also not strictly constant, as in ondulin. Focusing on your needs, you can purchase sheets with a width of 1.1 to 1.25 m and a length of 2 to 12 m.

As a rule, a protective layer of polymer is applied to the outside of the steel sheet. Instead of a polymer coating, galvanizing can also be applied, but such a corrugated board will not have sufficient protective properties. After all, it is the polymer film that gives the metal sheets color and significantly extends its service life. By the way, a rich color range is one of the advantages of corrugated board over ondulin, the color scheme of which is limited to 4-6 shades.

Easy installation and crate requirements

Installation of both ondulin and corrugated board requires certain skills.In the process of laying each material has its own characteristics, which, it is possible, can partially affect the choice of the buyer.

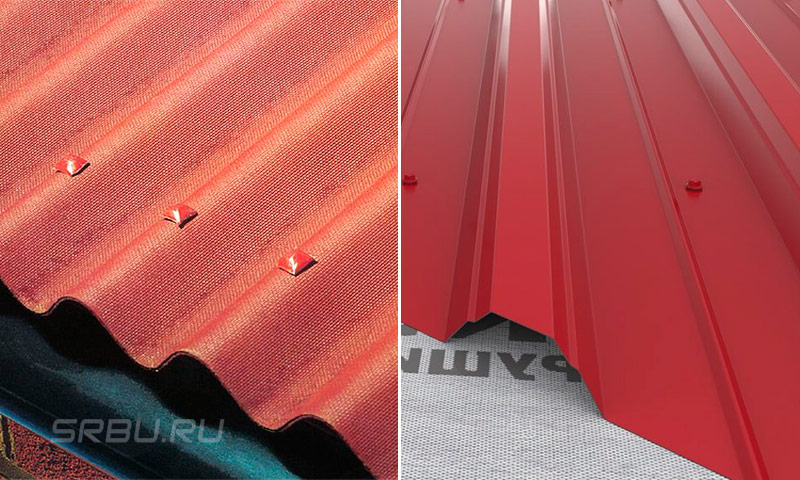

Ondulin is very easy to process: it is easily cut with a conventional hacksaw and pierced with nails. Due to the good flexibility of ondulin and the simplicity of its cutting, this material can be considered ideal for laying in hard-to-reach areas of the roof, as well as in areas of complex shape.

Installation of the roof from ondulin is best done in warm, but not hot weather, the permissible temperature range for installation is from –5 to + 30ºС. This is due to the features of the material, which we will talk about later. Moving along the surface to be mounted, one should step only on concave sections of the sheet, i.e., on the lower waves.

Arrangement of the base for the ondulin flooring may require more investment, since this material requires a more frequent step of the crate. The manufacturer himself recommends an angle of inclination of 150 and more to fill the crate with a pitch of 65 cm, if the angle of inclination is less than 150, then the step of the crate should be reduced to 45 cm. But as practice shows, with an angle of inclination of the roof less than 150 a solid base is best. The blame for the lack of rigidity of the material.

Especially to the recommendations for the arrangement of the crate, it is necessary to listen to those who live in regions with high snow cover. You can see examples of ignoring these recommendations below.

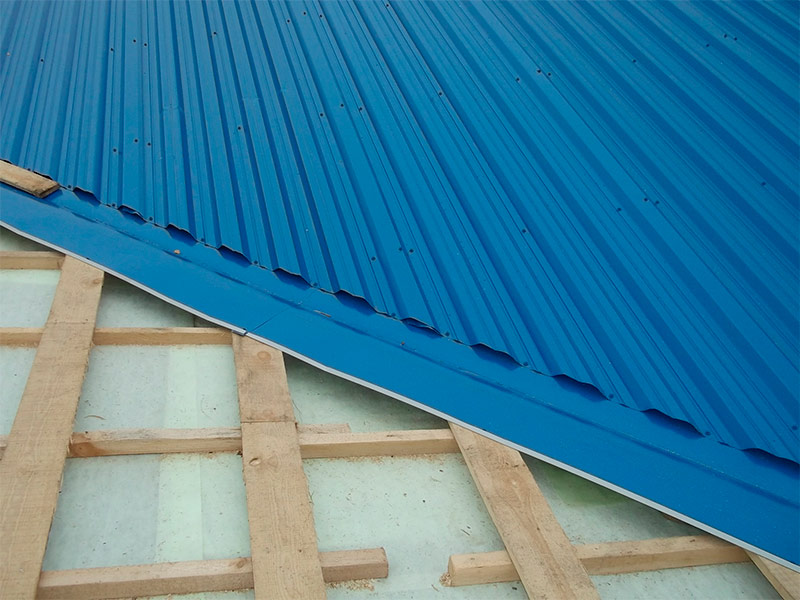

Installation of roofing from corrugated board is also not particularly difficult. This can be done at any time of the year, because unlike ondulin, the strength characteristics of corrugated board are independent of temperature. Another plus of this material is that you can always buy sheets of the right length, finished or made to order, which means you have the opportunity to minimize the number of joints.

However, the corrugated board has its own drawbacks that impose restrictions or create difficulties during installation.

Firstly, cutting steel sheets is not as easy as cardboard bitumen, so cutting the material will require more time and effort from you.

Secondly, it is strongly not recommended to bend sheets of corrugated board, because this violates the integrity of the protective coating. From this it follows that this material is good for even sections of the roof, if the roof has an irregular shape, certain difficulties will arise during installation.

Thirdly, the metal has a high coefficient of thermal conductivity, and in the summer literally heats up under the sun. We will not speak about the violation of the microclimate in the subroof space caused by this. But even the temperature difference leads to the formation of condensate on the inner surface of the roof, which means that there is a need for a waterproofing device. And this, as you understand, extra financial investments and labor.

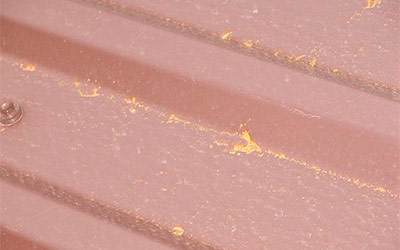

Fourth, scratches on the polymer coating that occurred during transportation or installation must be painted over with a special composition, otherwise metal corrosion will begin.

Laying each of these materials has its own nuances. In each case, the success of the work depends on compliance with a number of rules and strict adherence to the manufacturer's instructions. Ondulin is easy to process, but will require more funds for the arrangement of the crate. Working with corrugated board is more complicated, but the material does not require a crate with frequent steps.

Strength and other physical and mechanical characteristics

Ondulin bends well along the wave, and this is one of its main advantages. Due to this property, the material is indispensable for coating roofs with complex geometry. You can cut it with a simple hacksaw, although with an electric saw, of course, it will go faster.

But ondulin cannot be called durable material. Even relatively small mechanical influences can cause its destruction. Of course, he will withstand the weight of a half-meter layer of snow.But after falling on the roof of thick branches of trees during a gusty wind and even after a large hail, a significant part of the cover will probably have to be replaced.

It is also not recommended to walk on the roof covered with ondulin, especially in extreme heat, when the material softens, or in frost, when, on the contrary, it becomes excessively brittle.

The strength of the corrugated board is much higher, which is due to the presence of profiled stiffeners. It easily withstands not only static, but also dynamic loads. In addition, unlike what we observe with ondulin, the ambient temperature does not affect the strength characteristics of corrugated board.

At the same time, the sheets of corrugated board are not designed for bending, since this will damage the protective coating. This means that this material is suitable for roofing only with a relatively simple configuration.

Decking has greater strength, but ondulin is more flexible. Which of these material qualities to give preference to depends on the specific tasks facing the builders.

Material weight

Ondulin is a fairly lightweight material. A square meter of coating weighs about 3 kg (for comparison: ordinary asbestos slate is four times heavier - 12 kg / m2), i.e., the weight of a standard-sized sheet is ~ 6 kg. This greatly simplifies the transportation and handling of the material. With the lifting of the sheet on the roof and fixing it there, if necessary, one person can also do a good job.

Decking is a bit heavier: one square meter of material weighs 6-7 kg. However, this is not so much. At least, special transport will not be required to transport corrugated board.

Decking is heavier than ondulin. However, both of them are lighter than the usual asbestos slate.

Longevity and service life

When building a house, we hope that we build for centuries. How long he actually will stand, depends on many factors, which we will not understand today. But how soon will he need a major overhaul? We specify the question in order to remain within the framework of our conversation today: how soon will the roofing material have to be replaced?

Manufacturers claim that the life of ondulin is 40-50 years. However, at the same time they guarantee the waterproofness of the material for only 15 years. Of course, potential buyers have a reasonable question: who will agree to live under a leaking roof for 25-30 years? From the reviews of some users it follows that the euro slate, sometimes, has to be changed after 10 years. This figure is better for those who decide to cover the roof of their house with this material.

The guaranteed service life of corrugated board is 25-30 years, but in fact the material remains usable for 50 years or more. The most important thing during transportation and installation is to carefully treat the protective polymer coating. However, even steel affected by corrosion remains waterproof for a long time.

The durability of the corrugated board is much higher than that of ondulin.

Fire safety

Ondulin, which is essentially cardboard impregnated with bitumen, is easily ignited and burns actively. It is this drawback of this material that limits its scope. In particular, ondulin cannot be used to cover the roofs of schools, kindergartens, hospitals.

Ondulin manufacturers are working to reduce the fire hazard of their products. Various additives introduced at the stage of pressing the fibers, significantly reduce the combustibility of the material. The ondulin produced today, as a rule, has KM5 (highest) fire safety class (ignition temperature - 230-300 ºС).

Steel sheets of corrugated board do not support combustion, so it is allowed to use it as a roofing material for structures of various purposes.

Ondulin, unlike corrugated board, burns well, and in case of fire, the roof covered by it will become another way of spreading the flame.

Sound absorption

We all want that extraneous sounds do not interfere with a relaxing holiday in our own home. What material roof will most contribute to this?

Despite the presence of a polymer coating, steel sheets of corrugated board remain very sonorous. All sounds - the sound of rain, the drum roll of hail, the sound of bird's claws, etc. - not only are not suppressed, but also amplified. If you do not make effective sound insulation, they will be clearly audible in all rooms on the upper floors.

Ondulin, unlike corrugated board, perfectly absorbs all sounds: the sound of rain becomes like a light rustling, and the birds move silently on the roof, not disturbing your morning sleep.

Ondulin is a material with good sound-absorbing properties, which cannot be said about corrugated board.

Snow retention

From the inclined sections of the roof covered with ondulin, due to the roughness of the surface of the latter, the snow leaves with difficulty. In regions with high snow cover, this can lead to heavy loads on the material, even its destruction. On the contrary, it easily slides off the corrugated board.

Which is better - the constant gathering of micro-avalanches or the accumulation of large snowdrifts on the roof - is a moot point.

Preservation of appearance during operation

What material is able to maintain its aesthetic appeal for many years? Will a house with an ondulin or corrugated roof look longer like a Christmas toy?

Ondulin is not subject to corrosion. It is resistant not only to moisture, but also to chemically active substances - alkalis, acids, oil products. It will not be destroyed even in regions whose atmosphere is saturated with industrial emissions. But this material is “not friendly” with the sun: for 2-4 years, its color fades noticeably, fading under the influence of ultraviolet radiation. It does not tolerate euro slate and temperature differences: at low air temperatures it becomes brittle, while in the heat, on the contrary, it softens, spreading a characteristic bituminous smell. In both cases, the risk of mechanical damage to the material increases.

Ondulin manufacturers unanimously claim that their products have absolute biostability. However, as practice has shown, this is not entirely true. This material really is not subject to decay. But literally after 2-3 years, moss begins to grow on it. The reason for this is the roughness of the euro slate: the dust lingering on its surface, being moistened, serves as an excellent medium for the growth of various crops. First of all, as a rule, shaded places turn green. The attractiveness of the roof from this, as you know, is significantly reduced.

Unlike ondulin, corrugated board does not fade in the sun, so manufacturers boldly take on the release of sheets of a wide variety of colors, because a bright roof will delight the eye for many years. Thanks to the polymer layer, the material does not corrode under the influence of precipitation and other negative factors.

However, if the protective coating is damaged for some reason, the sheet will begin to rust quickly. Since steel, which has a high coefficient of thermal conductivity, heats up very strongly in sunny weather, condensation forms on the inner surface of the roof, which increases the risk of starting corrosion processes.

Ondulin quickly fades in the sun, and in the absence of proper care, it is also covered with islets of moss. The corrugated board is devoid of such shortcomings, but has its own - if the integrity of the protective polymer coating is violated, the steel sheet begins to corrode.

Material cost

And finally, the last option in our list (but not the last one in importance) is the comparison parameter: which is cheaper - ondulin or corrugated board?

A square meter of ondulin will cost you 200-250 rubles. This is only 30% more expensive than ordinary asbestos slate: such a difference in price is fully justified by the advantages that you will get with new material.

The price of corrugated board can vary in a wider range - from 300-350 rubles / m2 up to 500 rubles / m2, and sometimes higher.However, as the experience of professional builders shows, profiled sheets of different price categories practically do not differ in quality, so you should focus on the lower limit of this range.

Decking will cost you a little more than ondulin. However, given the high strength and long durability of this material, many buyers prefer to neglect such a difference in price.

The final comparison of ondulin and corrugated board

|  | |||||||

|---|---|---|---|---|---|---|---|---|

| Ondulin | Decking | |||||||

| Mounting | Easier handling, more crate costs. | Harder handling, less crate costs. | ||||||

| Strength | It breaks easily and is very susceptible to temperature fluctuations. | Withstands significant static loads. | ||||||

| Weight | Lightweight material. | Heavier than ondulin. | ||||||

| Life time | Average. | Big. | ||||||

| Fire safety | It is subject to burning. | Not combustible. | ||||||

| Sound absorption | Absorbs noise well. | Enhances noise. | ||||||

| Snow retention | High. | Low. | ||||||

| Preservation of appearance | It burns out in the sun, saturates the dust and grows with mosses and lichens. | If the integrity of the polymer coating begins to corrode. | ||||||

| Cost | Below. | Higher. | ||||||