We find out: which bath is better - cast iron, acrylic or steel

In a good bath it is pleasant and comfortable, I don’t even want to get out of warm water. However, in addition to convenience, many pay attention to a beautiful design. After all, today there is plenty to choose from - not like before, when only standard cast iron products were available. It’s just sometimes difficult to understand which bath is better - a cast iron or acrylic or steel bath. These three materials are the most popular, and today we will compare them and determine the leaders.

Content:

What are cast iron, steel and acrylic bathtubs

Cast iron

Strong and reliable, well-kept heat products made of cast iron (which is an alloy of iron with carbon) appeared the very first. And it happened in 1925, in Spain, near Barcelona. The Rock brothers decided to expand the range of their cast iron radiator factory by launching the production of cast iron bathtubs. And to this day, ROCA is one of the recognized world leaders in this direction. The products of this brand are of high quality, durability and a variety of colors.

In Europe, a decrease in the total number of cast iron products is noticeable, they are gradually replaced by steel baths, easier to transport, cheaper and more environmentally friendly to manufacture. Cast iron bathtubs are produced by only a few companies. The most famous are Jacob Delafon, PORCHER, as well as ROCA. In Russia and other CIS countries, they are still produced in large quantities, but only in a couple of standard sizes, as well as with a small selection of shades.

Note that European cast iron products have a more beautiful and diverse design. For example, there may be handles on the side or armrests, the bottom increases due to a change in the angle of inclination of one of the backs. Sometimes one backrest is removed altogether for convenience. And the design of imported products can be anything: from classics with the possibility of embedding to a luxurious English style.

A properly made cast iron bathtub should have walls of at least 0.5 centimeters and strong enamel applied in factory in two steps. Cast iron alloy has in its composition certain amounts of manganese, silicon or sulfur, giving it additional strength. Enamel coating can last from 10 to 30 years, possibly longer (depending on loads).

+ The benefits of cast iron bathtubs

- Huge service life (up to half a century);

- Resistance to aggressive action;

- Heat preservation;

- The absence of pores on the surface;

- Noiselessness;

- Color depth;

- Ease of cleaning.

- Cons of cast iron bathtubs

- Heavy weight;

- It is difficult to transport, carry for installation and assembly;

- Lack of variety in configurations. They can be made only rectangular or oval.

Steel

At a cost, a steel bath is more attractive than a cast iron one. Moreover, the price may differ by two to three times. This is sometimes a weighty argument when deciding which bath is best - cast iron or steel. In addition, many consumers like the fact that products made of steel are able to take almost any shape. In addition to the traditional rectangular and oval (like cast iron), these are very convenient and compact corner designs, as well as polygonal, round, asymmetric.

Similar products are made from steel sheets from a thickness of 0.23 centimeters (thin-walled baths) to 0.35 centimeters (standard bathtubs). Acrylic-based enamel covering the steel surface is less thick than cast iron. But modern technologies for its application allow you to create a fairly reliable and durable coating.

Among foreign companies producing high-quality steel products, one can mention the Finnish company Ido, the French - Porcher and Jacob Delafon, the German - Bamberger and Kaldewei, the Italian - Ariston, the Spanish - ROCA. They weigh from 25 to 30 kilograms, are elegant in design and have a good enamel finish. Especially a lot of innovative technologies are used by Bamberger. For example, Anti-slip coating, anti-slip, Enamel-plus, repellent dirt. Warranty for baths - 30 years.

+ The benefits of steel bathtubs

- Not too high a price;

- A variety of shapes and sizes;

- Wear resistant coating;

- Light weight.

- Cons of steel baths

- They do not keep heat as well as cast-iron;

- Too “loud” (loud noise of poured water is clearly audible);

- Able to bend under the body of a heavy person.

Acrylic

This material began to be used for the production of bathtubs later. Its full name is methyl acrylate. It is a synthetic polymer and is made from acrylic acid. It turns out a substance resistant to abrasion, ultraviolet and oxygen. Its surface is pleasant, smooth and warm to the touch.

To make an acrylic bath, use one of two methods:

- They take an acrylic sheet of a suitable size, and then bend it in the vacuum chamber as needed. The resulting container is not too strong: its walls are easily bent, and when pouring water, they can bloat. Therefore, you need to strengthen the bath: its surface in several layers is coated with epoxy resin, laying with fiberglass. The more layers, the stronger the bath.

- Injection technology involves the use of a fiberglass frame on which acrylic is applied. As a result, a more durable product is immediately obtained than made according to the method described above.

In any case, the “correct” acrylic bath should have a wall thickness of at least 4-6 millimeters. When tapping on its sides, too loud a sound should not be heard. This may mean that the manufacturer cheated, deciding to save on the reinforcement process. Next, we mention the manufacturers who produce high-quality acrylic products. This is the Czech company Ravak, Polish - Cersanit and Kolo, Spanish - Pool Spa, Dutch - Riho, German - Duravit, Russian - Aquanet.

When the landlord decides which bathtub is better, acrylic or cast iron, before equipping his bathroom, he often outweighs the acrylic. Because of its lightness, beautiful and varied shape.

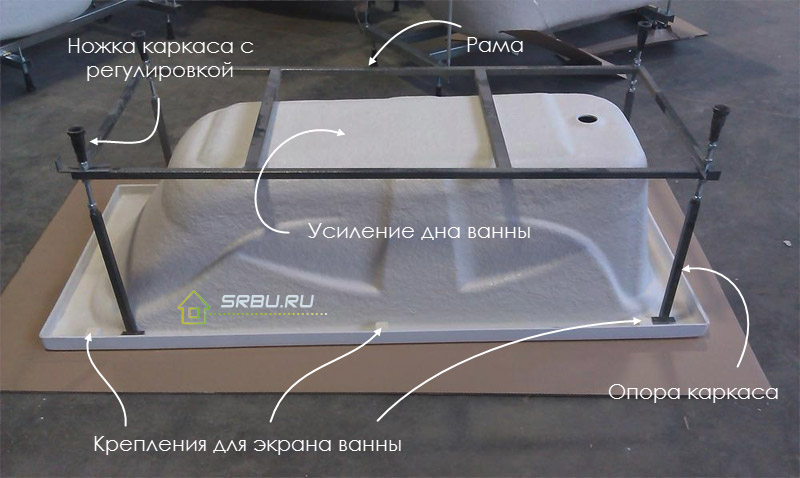

The device of an acrylic bath and its frame.

The device of an acrylic bath and its frame.

+ Pros of Acrylic Baths

- Acrylic perfectly retains heat;

- The abundance of various modern devices (for example, hydromassage) makes acrylic bathtubs one of the most functional;

- Light weight;

- Huge selection of shapes and sizes.

- Cons of acrylic bathtubs

- Difficulty in caring;

- May bend during use;

- Fear of acrylic of too high temperatures;

- Short service life in comparison with cast iron and steel models.

Easy installation

It’s not so easy to bring a heavy cast-iron bathtub into the house - only one person can’t handle it. This is the reason for the difficulty in the installation of such products. They must also be firmly fixed on a level plane. They are usually placed on four molded legs.

To install an acrylic bath, you will need to assemble a metal frame and only after installing the bath on the frame can it be connected to the sewage system. This somewhat complicates the process of its installation, but since all the parts are light, one person can completely cope with this.

Steel baths are also fixed on the legs, however, one person can cope with their installation. To significantly increase sound insulation, a layer of mounting foam is often applied to the surface of the product or the bottom is coated with Penofol. In general, the installation of a steel bath is the simplest.

Soundproofing a steel bath: on the left with Penofol, on the right with mounting foam.

Steel bath

Acrylic bath

Cast iron bathtub

The results. The most simple to install can be called steel baths (although, in the case of mounting foam, the process is somewhat complicated). The second place belongs to acrylic bathtubs, where you have to tinker with the manufacture of the frame.And cast iron products, heavy and bulky, close the rating.

Easy care

If the enamel on cast iron is applied qualitatively and has a sufficiently thick layer, then the coating is very durable. And even if the stain penetrated deep into the enamel, then it can be removed in almost any way, including chemicals and mechanical stress. And the housewives do it with great success.

Steel products are coated with thinner enamel, which, accordingly, needs to be cleaned more accurately than in the previous case. Especially when using abrasive products. Otherwise, you can damage the surface, which will then be difficult to restore.

Acrylic bathtubs are cleaned gently, using mild care products and without using strong abrasives and aggressive “chemistry”. This will prevent cracking and premature failure of the product.

Cast iron bathtub

Steel bath

Acrylic bath

The results. For this item, the most unpretentious of our products were cast iron, and acrylic modestly moved to the very last place, the third. Steel bathtubs took an average position. However, the steel models mentioned above, coated with the innovative Enamel-Plus compound, can also claim to be a leader in terms of ease of maintenance.

Life time

Cast iron products are not in vain still popular - they are intended to please their owners for at least 50 years, and this is a very decent time. Steel baths can safely last 20-30 years. Cast acrylic products can withstand at least 15 years. But provided that their walls have a thickness of at least 4 - 5 millimeters.

Cast iron bathtub

Steel bath

Acrylic bath

The results. Cast iron has firmly established itself in the leading position - its durability is beyond doubt (but the technology must be observed in the manufacture of this material). Steel bathtubs are again in the middle of the rating, and acrylic products are in the closing position.

Degree of protection of coatings

This item is closely related to the care of products, so a little more. As already mentioned, the enamel with which cast iron is coated has a smooth surface, resistance to various reagents and mechanical stresses. In the manufacture of high-quality cast-iron bathtubs, experts carefully check the quality of enamel at each stage, applying it with a layer from 0.8 to 1.2 millimeters. Firing occurs at a temperature of 110 degrees. So the protection of such a bath is “one hundred percent”.

Enamel on steel bathtubs is also of good quality, but due to its thinner layer, the protective coating is somewhat less reliable than in cast iron products.

Acrylic is fragile enough, he does not like when something heavy is thrown at him. Because of this, cracks may appear. Which, of course, are quite amenable to restoration, but all this adds to the hassle. In addition, stains from various coloring agents and scratches very easily remain on the acrylic surface. Of all coatings, acrylic should be treated most sparingly.

Cast iron bathtub

Steel bath

Acrylic bath

The results. And again the team of cast-iron bathtubs receives a gold medal, the second place, according to tradition, was taken by steel, the third goes to acrylic products.

Variety of shapes

Let's start with cast iron. There are few options, or rather, only two. If you want - choose a rectangular bath, if you want - get a more modern oval bath. The third, as they say, is not given. After all, cast iron, although very strong material, is still fragile. Therefore, it, unlike forged steel, does not allow the construction of complex shapes.

That is why for those who dream of a more original design, the answer to the question is clear: which bath to choose - acrylic, steel or cast iron. Naturally, in this case, the last option immediately disappears. But acrylic and steel keep up with this parameter.Both materials allow you to recreate any form that is pleasing to the soul. If you want, the bath will be perfectly round; if you want, it will be curiously curved or made in the form of a polygon. A very practical form for small rooms - triangular. It makes it easy to fit the bathtub into a corner without taking up much space.

A variety of shapes of acrylic and steel bathtubs:

Square

Square

Non-standard

Non-standard

Quadrant

Round

Round

Oval

Rectangular

Multifaceted

Multifaceted

Semicircular

Rectangular with a ledge

Acrylic bath

Steel bath

Cast iron bathtub

The results. According to the results of the study there are two winners at once. Championship laurels divided steel and acrylic products among themselves, and cast iron quietly faded into the background.

Variety of sizes

European-made cast-iron bathtubs can have a length of 150 to 180 centimeters, and a width of 60 to 90 centimeters. The standard length of the lower (inner) part is 110-120 centimeters. Modern technologies (changing the angle of the backrest, for example) make it possible to increase this size to 130-140 centimeters. Domestic bathtubs made of cast iron are 70 centimeters wide and a length varying from 120 to 150 centimeters.

The variety of shapes of steel and acrylic products suggests a variety of sizes. As an example, here are steel bathtubs manufactured by the German company Kaldewei. The large model of this Corpostar brand has dimensions of 190 by 90 centimeters, and the small Miniform model has 157 by 70 centimeters. The Japanese-style model Kusatsu Pool is characterized by increased depth (81 centimeters) and compactness (140 per 100 centimeters).

Equally diverse in size are bathtubs made of acrylic. They can be large and small, wide and narrow, deep and not very. Corner and round options are available with different side sizes and diameters. If we talk about rectangular and oval models, then their bowl can have a width of 70 to 170 centimeters, and a length of 120 to 190 centimeters.

Acrylic bath

Steel bath

Cast iron bathtub

The results. More modern steel with acrylic were again in the lead, leaving behind solid but conservative cast iron. They make it possible to choose a product for any bathroom and for any purpose. For example, a large round bath can be used immediately for two. A compact corner option is for a small apartment.

Installation types

There can be three options: installation along one of the walls (most common), angular placement and installation in the middle of the room. The latter option is used for large bathrooms when using large oval or round bathtubs. Which are often equipped with hydromassage and other pleasant additions.

Corner models are produced both symmetrical and with different sizes of sides adjacent to the walls. As a rule, the side opposite the corner has a rounding. It is not only practical, but also looks beautiful.

Cast iron bathtubs, as a rule, are placed along the wall, less often they are placed in the center of the room. In the corner, due to the design features, they cannot be installed. As for steel and acrylic products, they can be mounted in any of three options. Choosing the right model is not a problem.

Acrylic bath

Steel bath

Cast iron bathtub

The results. Once again, we have two leaders - steel and acrylic products have more installation options. Cast-iron bathtubs remained in the shade.

Ease of use

Here we will consider what degree of comfort products from various materials give us. Let's start with the temperature of the water - for a pleasant bath, it is important that it does not cool longer. Good old cast iron in this sense is very good - it keeps the water warm for a long time. However, modern acrylic also boasts good heat saving. But steel - alas - quickly cools the water. In addition, she has one more drawback - she strumming heavily when the bath is typed.Cast iron and acrylic are very quiet.

The walls of a bathtub made of cast iron will never bend. Now we will consider the following two products by this parameter, determining which bath is better - an acrylic or steel bath. Steel can well maintain its position, not rushing under the weight of the body, which can not be said about acrylic. The deflection of the walls is its main drawback, the metal frame is designed to cope with it, on which the bath is mounted. This is most relevant for people who are overweight.

Cast iron bathtub

Acrylic bath

Steel bath

The results. According to the considered parameters, the most convenient are cast iron products. Acrylic is not without flaws in this regard, so they can share the second place. Steel baths are somewhat inferior in this respect to acrylic, but in some cases they can perform on an equal footing. Also, bathtubs made of steel and acrylic are often equipped with all sorts of comfortable seats, handles, armrests.

Instrument weight

The most difficult are bathtubs made of cast iron. They weigh at least 120-130 kilograms. Such a solid weight (sometimes reaching up to 150 kilograms) provides good stability, but significantly complicates installation work. Which will cost more than installing a steel or acrylic bath.

A European-made steel bath with walls from 2.5 to 3 millimeters is much lighter than a cast-iron, and several times. Its weight is from 25 to 30 kilograms approximately.

The most “weightless” material can be called acrylic. If the bath made of it has a length of 150 centimeters, then its weight ranges from 15 to 20 kilograms. Products with a length of 170 centimeters weigh from 20 to 25 kilograms. By the way, when buying, pay attention to this: a bathtub that is too light, very different in weight from these indicators, may turn out to be of poor quality. Otherwise, the manufacturer faked it, making the product with less than the number of reinforcing layers that followed.

Acrylic bath

Steel bath

Cast iron bathtub

The results. In the first place we define acrylic products. On the second - steel baths, and on the third - cast iron, completely unbearable.

Price

Let's start again with cast-iron appliances. Domestic models without special "bells and whistles" and jewelry will cost 50-70 dollars. European baths will cost more: from $ 200 and up. The price for premium collections by PORCHER and Jacob Delafon can reach up to 450-700 dollars.

Bathtubs made of steel are twice (or even three times) cheaper than cast iron. If we talk about European products, then its price will start at $ 100. Products of Russian manufacturers will cost from $ 50.

Acrylic appliances have a very wide price range. And often they are equipped with a hydromassage system, which should also be taken into account when comparing the cost of different types of bathtubs. The most budget option will cost from $ 60 (production in China). Russian products will cost from $ 100, European - 130-200 dollars.

Steel bath

Acrylic bath

Cast iron bathtub

The results. The first place for cheapness belongs rightfully to steel bathtubs. In second place are acrylic products. Cast iron completes the rating.

The final comparison of cast iron, steel and acrylic bathtubs by parameters

|  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|

| STEEL BATH | ACRYLIC BATH | CAST IRON BATH | |||||||

| Easy installation | 9/10 |

8/10 |

7/10 |

||||||

| Care | 8/10 |

7/10 |

9/10 |

||||||

| Life time | 9/10 |

7/10 |

10/10 |

||||||

| Degree of protection of coatings | 8/10 |

7/10 |

9/10 |

||||||

| Variety of shapes | 9/10 |

10/10 |

7/10 |

||||||

| Variety of sizes | 9/10 |

10/10 |

8/10 |

||||||

| Installation types | 10/10 |

10/10 |

8/10 |

||||||

| Ease of use | 8/10 |

9/10 |

10/10 |

||||||

| Instrument weight | 9/10 |

10/10 |

6/10 |

||||||

| Price | 10/10 |

9/10 |

8/10 |

||||||