Vinyl laminate - characteristics, advantages and disadvantages

Not so long ago, a new type of flooring appeared on the building materials market - a kind of “hybrid” of laminate and linoleum. This material immediately aroused the interest of potential buyers. Naturally, a lot of questions arose, and the most important of them - does a vinyl laminate have flaws? After all, the quality of already familiar products is time-tested, but how the novelty will behave is still unknown. So let's get to know this “Mr. X” closer.

Content:

Structure and Design Features

As you know, everything new is well forgotten old. So vinyl flooring, which is just beginning to gain popularity in the field of interior design, oddly enough, has existed for quite some time. Their "ancestor" is the well-known PVC tile, which appeared in the 30s of the twentieth century. Of course, it cannot be compared to its current counterparts, however, there is still a “kinship” between old and new models.

And what are the properties of modern vinyl floors, what is it and how do they differ from their prototype? Thanks to advanced technologies, these products have the widest structural and color gamut, a high level of wear resistance and unique design features.

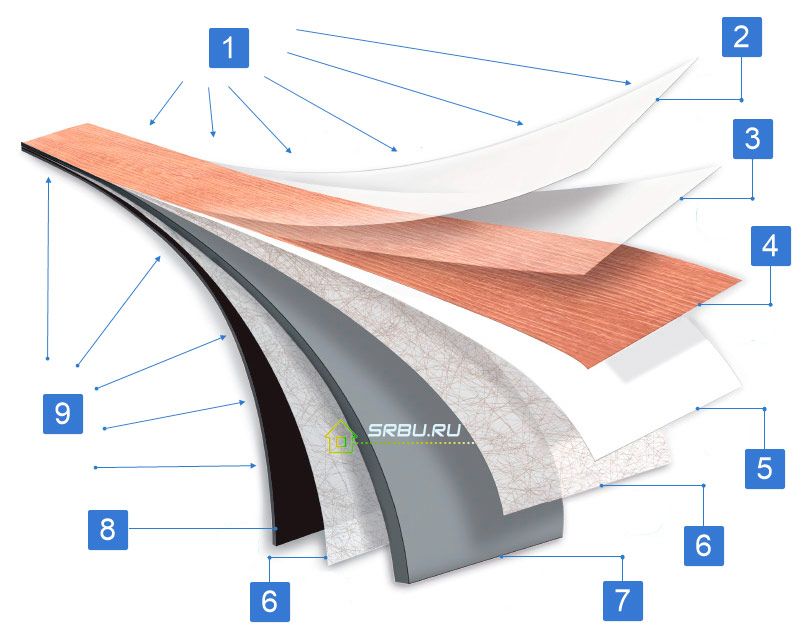

Vinyl flooring structure:

- 1. UV treatment to increase light fastness;

- 2. Polyurethane top layer;

- 3. A transparent protective layer of durable PVC (protects the coating from abrasion and mechanical damage);

- 4. A color layer with a printed image (provides decorative qualities);

- 5. Fiber optic layer - provides a reflective effect and provides the best realism;

- 6. Fiberglass - provides protection of a covering on a gap and its flexibility;

- 7. PVC base with the addition of finely divided mineral chips;

- 8. The bottom layer is a heat-insulating substrate (not provided for in all models);

- 9. Adhesive layer (present in certain types of coating).

Vinyl coating options:

1. Imitation of a laminate (rectangular strips with dimensions characteristic for a laminate board - 100 × 920 mm and 180 × 920 mm).

2. Square tile with or without lock (sizes - from 300 to 600 mm).

The standard thickness of vinyl products is 1.5-3.5 mm, however, some manufacturers have more thick flooring in their assortment.

Wear classes

There are three classes of wear resistance of vinyl coatings that determine their strength characteristics:

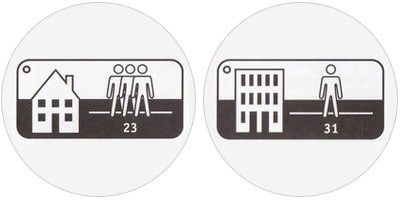

1. Household products (23, 31 class).

Designed for finishing floors in private homes and apartments. Coatings have a minimum thickness, but differ in a wide variety of species. Warranty period is 5-6 years.

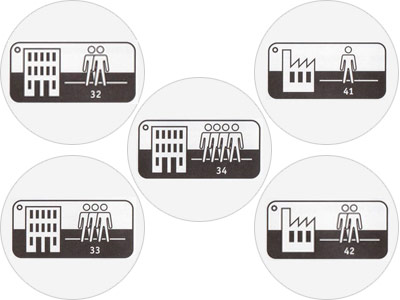

2. Commercial vinyl laminate (32-42 grade).

Applications include high traffic areas, office buildings, etc. Due to the thick protective layer, resistant to abrasion, such materials have a long service life - up to 15 years. Another advantage of this category of products are antistatic properties.

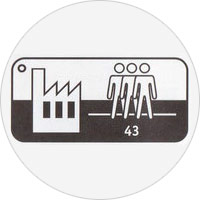

3. Special floor coverings (43rd class).

They are characterized by a maximum level of strength. They are recommended for arranging floors subject to increased mechanical stress. They can be used in production halls, garages, gyms, etc.

The cost of any coating directly depends on its wear resistance class.

Tip: when choosing a PVC laminate for finishing home floors, do not think about buying a more expensive commercial option, becausehousehold samples have a good abrasion resource, so it’s just not practical to overpay.

Unfortunately, vinyl floor coverings have not only a lot of positive characteristics, but they are not without some drawbacks. What specific qualities are more, we will consider further.

Advantages of a vinyl laminate

+ A variety of design solutions.

A wide color and texture range allows you to choose the type of coating for any interior. In addition, vinyl materials can be combined, due to which, the design of the floor will be unique.

+ High wear resistance.

All varieties of vinyl floors are resistant to mechanical damage and UV rays, so they can last 10-20 years. The defining criteria for a long service life are proper installation and further care.

+ Stain resistance.

Vinyl products of the printed type have a transparent wear-resistant coating that reliably protects the floor from dirt and all kinds of stains. Such material is quite easy to maintain and retains its original appearance for a long time. For homogeneous and composite products, the surface is more prone to contamination, which may require polishing or partial replacement of the plates.

+ Easy installation.

Vinyl laminate and tiles are laid quite simply and quickly, while any special skills are not required. The main requirements for ensuring the quality of installation are a smooth, clean and dry floor surface.

+ Water resistant.

The vinyl coating forms an airtight layer on the floor, which is practically water-tight, which makes it ideal for kitchens, bathrooms and toilets.

+ Ease of care.

The process of cleaning a vinyl floor consists of two stages: dry cleaning with a broom or vacuum cleaner, and washing the coating with non-abrasive cleaners.

+ Affordable cost.

The price depends on the appearance and wear resistance class of the material. Domestic coatings on average cost 13-20 euros per square meter, better and more durable products - 25-35 euros / m².

+ Comfort.

Vinyl coatings have an elastic and soft surface, so it’s nice to walk on them even barefoot. In addition, they have low thermal conductivity, so in winter such a floor will not be cold.

The disadvantages of vinyl laminate

Despite the presence of a considerable number of positive qualities, unfortunately, vinyl tile also has drawbacks.

– Toxicity and fire hazard.

In case of fire, vinyl releases toxic substances into the air, therefore, such coatings are not recommended to be laid in rooms where devices with open fire are present (gas stoves, fireplaces, etc.);

– Volatile chemicals.

The composition of vinyl products includes various chemical components, and some of them may emit toxic gases, which cause various diseases, irritation of the eyes and respiratory tract, after the coating is laid for the first time. The level of material safety is determined by its chemical composition and life.

– Chemical pigmentation.

In principle, vinyl floors are well resistant to various stains, however, some chemical elements can react with this material, forming indelible traces. Interaction with rubber (shoe soles, rugs, etc.), for example, can lead to such an unpleasant effect, so it is better to avoid such contacts.

– Inability to repair damaged areas.

High-quality and more expensive materials are characterized by high strength and a long service life, while budget options are quite weak in resisting damage. Unfortunately, restoration of vinyl coatings is impossible, therefore, when defects are formed on the sheet material, it must be completely replaced. Partial replacement can be made in the case of using tiled PVC coatings.

Mounting Features

In various types of floor PVC coatings, a specific installation method is provided:

- Products with a self-adhesive layer. Installation is carried out on perfectly smooth and clean surfaces.Fitting to the desired size is done before removing the protective film. Before gluing, the film is removed and the tile is carefully laid on the floor, avoiding the formation of air gaps.

- Vinyl coating without a self-adhesive layer. Provides for the use of special glue. A thin layer of adhesive is applied to the floor surface and left to dry for 15 minutes. The plates are fixed using a ramming roller.

- Locking coatings. They are mounted in the same way as a laminate board.

Before laying vinyl on concrete substrates, they must be pre-primed.