Circulation pump for heating: how to choose the best models

A heating circuit with a forced coolant circulation system is able to heat a building with maximum efficiency. This article will tell the owner of an individual house which circulation pump is best to choose for heating residential and utility rooms. At the end of the material you will find an overview of the equipment that has received the most favorable reviews from specialists and users.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

Purpose and principle of operation of the circulation pump

The circulation pump is designed for forced pumping of the coolant through all elements of the heating system. It prevents the formation of stagnant zones and increases the speed of heating water. Due to this, all heat exchange processes proceed with increased intensity, which positively affects the heating efficiency of the building.

Such pumps have a sealed metal casing, inside of which a shaft rotates with an impeller mounted on it. The unit is driven by an electric motor, all wiring elements of which are reliably protected from moisture.

The impeller rotating together with the shaft creates a vacuum in the inlet pipe, which sucks in water. The kinetic energy of rotation is enough for the liquid to be ejected from the discharge pipe with high pressure, which can be from tenths to several atmospheres. Due to it, the coolant is pumped along the heating circuit and returns to the pump again.

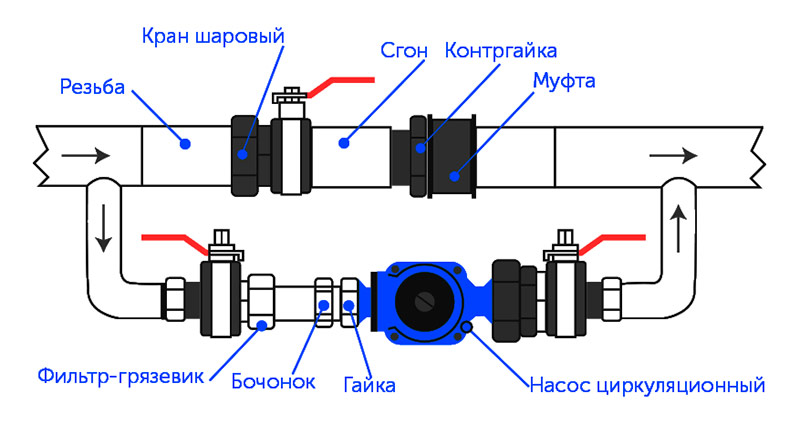

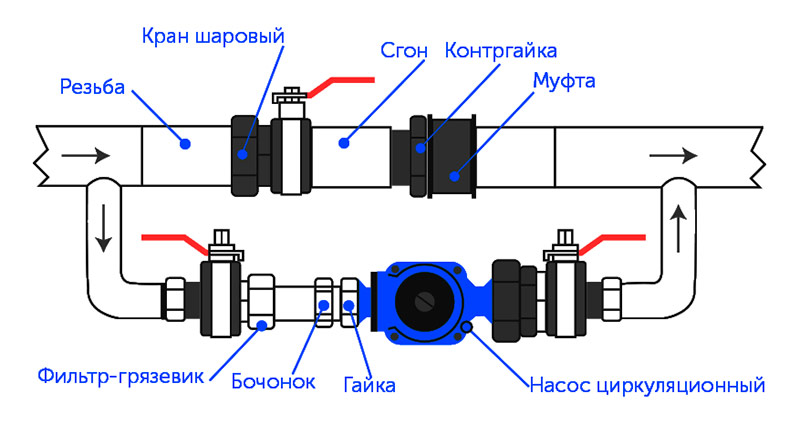

Installation diagram of the circulation pump in the heating system.

Types of circulation pumps

Specialists distinguish between two main types of circulation pumps installed in local heating systems. Each of them requires careful consideration.

Dry circulating pumps.

The design of dry circulation pumps eliminates the contact of the rotor of the electric motor with the pumped water. In this case, the impeller is separated from the rotor by the rings of the mechanical seal.

As a material for them apply:

- high-strength pressed carbon blends;

- stainless steel

- wear resistant ceramics;

- oxides of aluminum and tungsten.

The rings are pressed together by springs. When moving, they are rubbed tightly against one another. The thinnest film of water falling into the gap serves as an additional sealing element in the structure. The pumps of the old design instead of the mechanical seal used the stuffing box packing, which had to be periodically tightened or refilled as it wore to restore the original tightness. The ends of modern models do not require repair for 3 years or more.

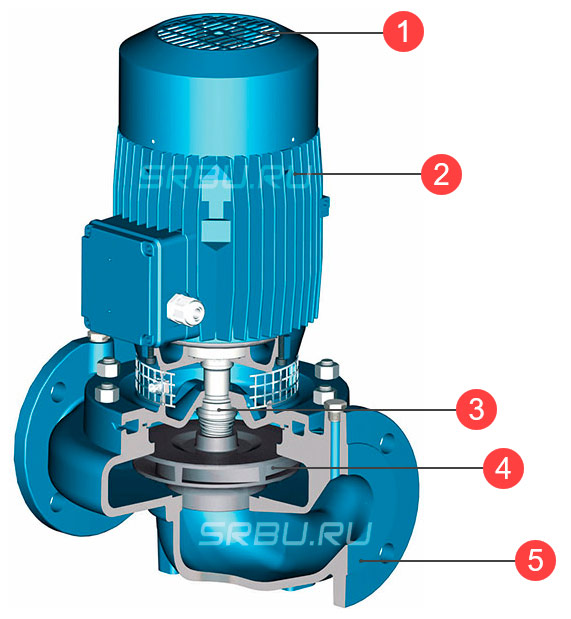

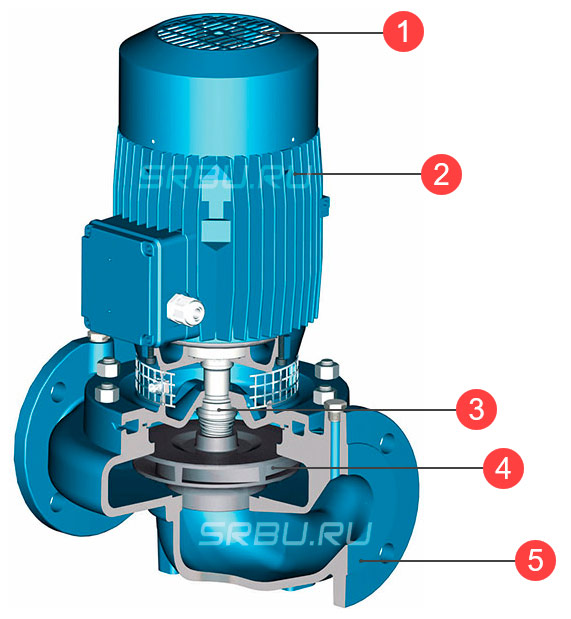

The device of the circulation pump with a dry rotor.

1. Motor fan.

2. Engine housing with cooling fins.

3. Sealing gland.

4. Impeller.

Features of the operation of dry type circulation pumps:

- high efficiency reaching 80%;

- increased noise level, requiring the installation of equipment in a separate room;

- stringent requirements to minimize suspended solids in water, leading to abrasive wear of seals;

- inadmissibility of prolonged idling without contact with the liquid.

Design options and installation positions of dry pumps.

Horizontal pumps

Horizontal pumps have a classic mounting option, in which the impeller and motor are located on the same level. The receiving pipe is located in the end part, and the discharge pipe is on the side surface of the housing.

Vertical pumps

Vertical pumps differ in the position of the motor above the working part. The receiving and discharge nozzles for them usually have the same diameter and are located on the same horizontal axis.

Block pumps

Block pumps are characterized by a compact design. The electric motor and impeller are often mounted in one housing. They are characterized by the end position of the receiving nozzle and the radial direction of the discharge pipe.

Dry circulating pumps are practically not used in domestic boiler houses, as in this case wet circulating pumps are best suited.

Wet circulation pumps

A distinctive feature of wet pumps is the direct contact of the motor rotor with the pumped liquid. At the same time, water plays an additional role in lubricating rubbing surfaces and cooling the motor. The live parts in this case are protected by a stainless steel cup separating the rotating shaft from the stator. In the manufacture of the rotor, ceramics and graphite are actively used. The case is usually made of bronze, brass or cast iron.

Features of wet circulation pumps:

- almost silent work;

- minimum maintenance;

- long term of operation;

- low efficiency, which rarely reaches 50%.

Modern models have a modular structure that facilitates inspection and repair. The inlet piping is attached to the pump using threads or flange connections. Due to the need for a uniform supply of cooling water to the bearing units, this type of equipment is almost always mounted in a horizontal position.

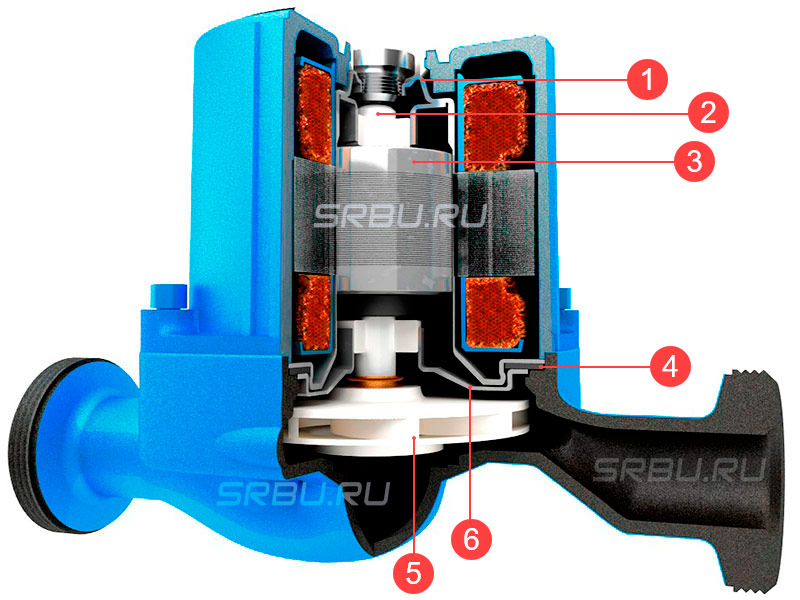

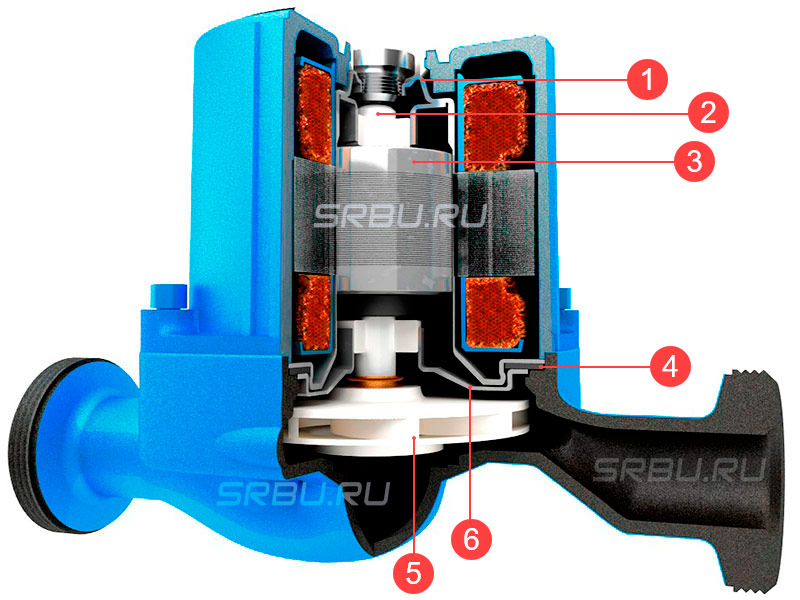

Wet rotor heating circulation pump device

1. A whole glass of wet rotor.

2. Ceramic shaft.

3. Wet rotor.

4. Sealing ring.

5. Impeller of the pump.

6. Cap.

Marking and technical characteristics of circulation pumps

The pump purchased for the heating system must be suitable for its intended purpose. When choosing, they are guided by the main technical characteristics.

Maximum head

It shows how high the pumped liquid can rise. This indicator should correspond to the number of storeys in the building. When installing a pumping station at some distance from the cottage, a certain margin is required to overcome the hydraulic resistance of the pipelines. For most country houses, models with a pressure of 4 to 8 meters are suitable.

Consumption

It indicates the maximum volume of fluid pumped per unit of time. It is calculated in m3/ hour or l / min. This indicator is taken into account when performing hydraulic and heating calculations of the designed system.

Nozzle diameter

It is directly related to the size of the piping suitable for the pump. The most running pipes in low-rise buildings 25 and 32 mm.

Installation length

The choice of location for installing the unit depends on it.

For user convenience, most well-known manufacturers include key features in their product labeling. A typical product name consists of:

- the letter designation of the type of pump and its material design;

- digital designation of the main technical characteristics.

Rules for choosing circulation pumps

The simplest knowledge of how to choose a circulation pump for heating will help the future user avoid mistakes during installation and operation of the system. The compliance of the technical characteristics of the pump with the installed heat exchange equipment depends on how quickly water will be pumped through the heating circuits, and what will be the heat transfer efficiency. Such an insignificant-looking unit can significantly affect the level of comfort and energy costs of a family to maintain a favorable microclimate in the house.

Fully rely on the advice of the seller in this case should not be. He is interested in implementing the most expensive model without taking into account the specifics of your home. It is advisable for the buyer to know the necessary technical parameters of the purchased equipment himself.

Pump Performance Selection

The maximum flow rate of the liquid pumped by the pump must correspond to the heat output of the boiler and the radiators installed in the house. Underestimated performance will adversely affect the efficiency of heat transfer, overestimated - will lead to unreasonably high costs for current operation.

The required flow rate can be approximately calculated using a simplified formula:

Q = 0.86 x P / dt

In this formula:

- Q - minimum required pump capacity in m3/hour;

- P - passport or calculated energy capacity of heating equipment in kW;

- dt is the temperature difference between the coolant in the forward and reverse circuits. For most systems, the amount of heating medium is taken 20about FROM.

The choice of the necessary pressure

The pressure of the pump used must exceed the hydraulic resistance of the system. The calculations used in engineering design are quite complicated. They take into account each tee, outlet, narrowing point, the shape of the radiators and the configuration of the heat exchanger in the boiler. In practice, it is convenient to use a simplified formula that can be used for small heating circuits:

H = N x K

Where:

- N is the number of floors of the building, including the basement, if it is heated;

- K - the average hydraulic loss of one floor. For two-pipe systems, it is taken within 0.7-1.1 meters, for collector-beam configurations, from 1.16 to 1.85 meters.

Calculation Example

For example, we will solve the problem of how to choose a circulation pump for heating a two-story house with a heated basement. The total area of heated rooms is 200 square meters. It is planned to carry out the wiring of the two-pipe type.

From the general rule for well-insulated buildings, when for every 10 m2 The area requires 1 kW of consumed thermal energy, we find the necessary boiler power, it is 20 kW. Applying the first formula, we get a minimum flow rate of 0.86 m3/ hour, which is rounded up to 0.9 m3/hour.

In our case, three floors are heated. For a two-pipe wiring, we accept the maximum value of the hydraulic resistance of the floor of 1.1 m of a liquid column. As a result of a simple calculation according to the second formula, we find the minimum pressure for the purchased pump 3.3 meters.

The fact that our building is more than 8 meters high should not bother us. The hydraulic system is in balance. The pump does not need to take water from zero and pump it to the top floor of the house. At the reception of the unit, the same column of liquid presses, helping it in work. It simply creates circulation, overcoming only the resistance of installed equipment and supply pipelines.

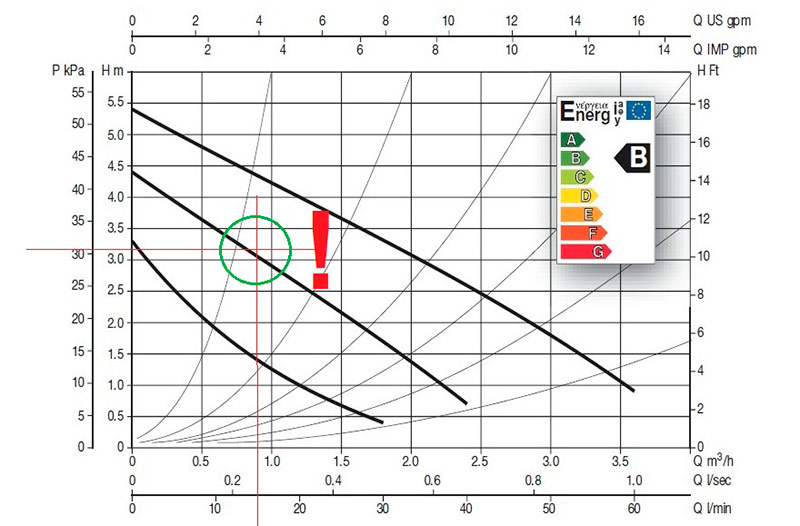

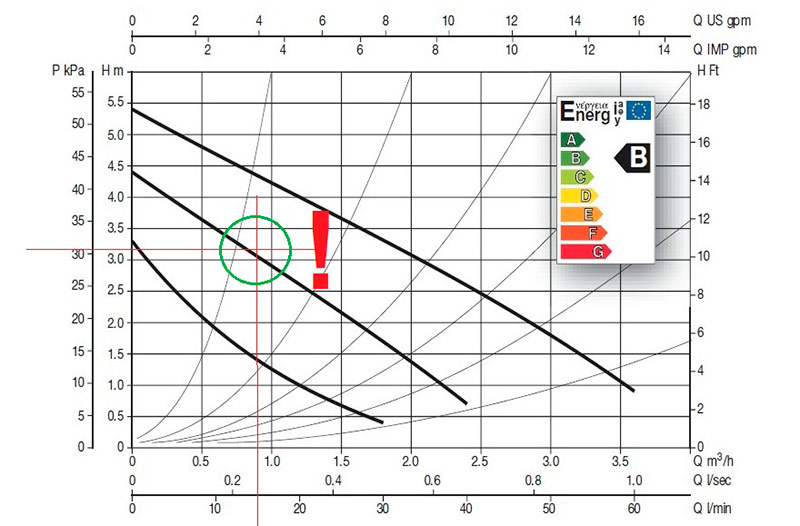

A hydraulic curve is applied to the passport of any circulation pump, showing the interdependence of flow and pressure in different operating modes. Choosing a specific model, you need to make sure that the working intersection point of the parameters found by us is in the middle third of the graph. In this case, the unit will achieve maximum efficiency.

The green circle is surrounded by the intersection point of the parameters we found, based on the calculation above.

For multi-speed pumps, the curve for the second speed should be taken as the basis for determining the operating point. During operation, the resistance of the system may change. The ability to switch to 1 or 3 speeds will allow you to adapt the equipment to the prevailing conditions.

Do not forget about the noise

We are considering the possibility of installing a circulation pump in a residential building. It must be remembered that the sound of a running electric motor can irritate households and interfere with their normal rest. In most cases, a noise level of 45 dB is considered acceptable, although some models reach 65 dB in operating mode.

The best place to install the pump unit is a separate utility room. If it has a common wall with a bedroom or a children's room, you should take care of additional sound insulation.

The best circulation pumps for heating an individual house

Leading manufacturers of pumping equipment produce units with a wide range of technical specifications. This allows the consumer to choose a model that is ideal for specific tasks and operating conditions. Therefore, the rating of circulation pumps presented to your attention includes not individual brands, but model lines from well-known brands.

Grundfos ups

Wet-type circulation pumps from a well-known Danish manufacturer are highly reliable and ideally suited for operation in heating systems. This line is represented by models with a capacity of 48 to 1083 l / min and a pressure of 4 to 13.2 meters. Compact units have an installation length of 130 mm, for more powerful ones it reaches 340 mm. Depending on the fluid flow rate, threaded connections G1 and G2 or flanges designed for pressures up to 10 atmospheres are used.

A feature of the products of this series are a cast-iron case and stainless steel as internal equipment. All models are waterproof. The manufacturer has provided three rotor speeds, which simplifies the selection of the optimal mode.

Pros of Grundfos UPS

- High reliability.

- Long service life.

- Minimal maintenance.

- Ease of installation.

- Economical energy consumption.

Cons Grundfos UPS

- Silent, but not silent.

- Unstable work at extremely high pressure.

- Sometimes there are claims to the quality of electrical equipment.

- The price could be lower.

Grundfos Alpha2

Another line of the same manufacturer, maximally adapted for use in local heating systems. A relatively small variation in technical characteristics is associated with this. The performance of the models is in the range from 40.0 to 60.12 l / min, and the pressure is from 4 to 8 meters. Mounting length standard - 180 mm. When connecting, pipe connections G1 and G2 are used.

Cast iron pump housing. The electric motor is powered by 220 volts AC. A feature of the models of this series is an increased level of moisture protection and a multifunctional automation system with displaying readings on the built-in display.

Such a pump itself chooses the optimal operating mode. Due to the presence of a frequency converter, energy consumption is saved. Overheating protection is provided.

Pros of Grundfos Alpha2

- High reliability.

- Profitability.

- Compact size.

- No maintenance is required for a long service life.

- Ease of installation, convenience and security of connecting to the electrical network.

- Low noise.

Cons Grundfos Alpha2

- High price.

- If the Alpha plug is missing or damaged, you have to order it at a specialized store.

Wilo star

The model range of a well-known German manufacturer includes centrifugal pumps with a horizontal shaft arrangement with a capacity of 50 to 83.3 l / min and a pressure of 1 to 7 meters. They are designed for pumping liquids with temperatures from -10 to 110 degrees Celsius. Mounting length 130 or 180 mm. Case material - cast iron.The shaft is made of stainless steel, the bearings are made of metallographite, and the impeller is made of plastic. The inlet and outlet nozzles are equipped with pipe threads.

The pump is connected to a 220 volt network using spring terminals. The equipment has a degree of protection IP44. There is the possibility of stepwise regulation of the speed of rotation.

Pros of Wilo Star

- German quality.

- Economical power consumption.

- Long life without the need for maintenance.

- Convenience of installation and connection.

- Light weight and small dimensions.

- Silent work.

- Acceptable price.

Cons Wilo Star

- The plastic of the terminal box and the speed controller loses its strength over time and may crack.

- High requirements for the absence of mechanical impurities in the circulating water. You need to use a good filter.

NeoClima TCP

The wet brand circulation pumps of the Greek brand, manufactured in China, are excellent for long-term operation in heating systems. The consumer has the opportunity to choose a model with a capacity of 40 to 170 l / min and a pressure of 4 to 8 meters. Mounting length standard - 180 mm. Pipe thread is used for connection.

The body of the product is made of high quality cast iron. The plastic impeller is mounted on a ceramic shaft. Graphite seals provide smooth running and quiet operation. The power regulator makes it easy to choose the optimal mode of operation.

Pros of NeoClima TCP

- Good value for money.

- Profitability.

- Low noise.

- Good equipment up to the FUM tape for connection.

- Reliable work.

- Minimal maintenance.

Cons NeoClima TCP

- There are claims to build quality.

- Impeller plastic is not designed for long-term operation in the presence of abrasive inclusions in water.

- The pipe thread is made with a margin. Requires a lot of reeling.

Whirlwind CN

Simple and reliable centrifugal pumps of domestic design are specially adapted for use in local heating networks. This brand is represented by a number of models with a capacity of 50 to 170 l / min. The created pressure reaches from 4 to 8 meters. Подключения ”and 1” pipe threads are used for connection. Operating temperature range from -10about C to +110about C at maximum system pressure up to 10 bar.

The main structural elements are made of corrosion-resistant materials: cast iron and aluminum. All models are compact in size and attractive in appearance. The electric motor is connected to a network voltage of 220 volts. Protection class IP44. There are 3 speeds with a switch on the terminal box.

Pros Whirlwind CN

- Simple and reliable design.

- Profitability.

- Modern design.

- Low noise.

- Long service life.

- Affordable cost.

- Small dimensions.

- Simple installation and convenient adjustment.

- No maintenance required.

Cons Whirlwind CN

- There are claims to build quality.

- Some models do not reach the technical specifications declared by the manufacturer.