Technical characteristics of steel heating radiators

To choose the right radiator for the heating system, it is highly desirable to know its main technical parameters. Otherwise, you may not get the result that you would like. Radiators do not have the most important indicators, so it’s easy for laymen to understand them. Take, for example, steel heating radiators, the technical characteristics of which we will consider in this material.

Content:

Design features and variety of steel heating radiators

High technology steel does not require evidence. This ductile, durable, flexible and malleable material lends itself well to welding and also conducts heat remarkably. So steel is suitable for radiators in many ways.

There are two types of steel radiators:

- panel;

- tubular.

Panel Type Radiators

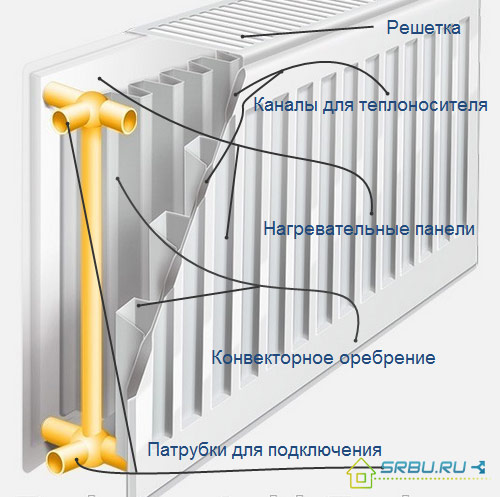

In the middle of this device are one, two or three panels. Each of them consists of two steel flat profiles welded along the contour for connection. The plates are stamped, after which oval vertical channels are formed on them - paths for the coolant. The production of these radiators is simple - roller welding connects stamped blanks. After that, the finished parts are fastened in two pieces with the help of nozzles.

The device of a steel convector radiator.

To increase heat transfer, manufacturers often equip panels from the inside with U-shaped ribs. For their manufacture, thinner sheets of steel are taken than for panels. Ribs increase convection. If several panels are connected in a row, then on both sides they are covered with covers. Depending on the number of heating and convection panels inside the radiators, the following types exist.

Type 10- This is a single-row radiator without a convector and without cladding.

Type 11- single-row radiator with one convector, without upper grille.

Type 20- double-row radiator without convector, with air outlet grille.

Type 21 - a two-row radiator with one convection fin, closed by a casing.

Type 22- two-row radiator with two convector fins, closed by a casing.

Type 30- three-row, without convection fins, top closed with a grill.

Type 33- a three-row radiator with three convector fins, closed by a casing.

As you understand, the heat transfer will depend on the type of radiator. Radiators of types 10 and 11 do not have convection and are able to give off heat only by heating the air.

The finished radiator is narrow enough, which is very convenient during installation. The price of such products is very affordable, so the owners of their own houses prefer to put just them.

Tube type radiators

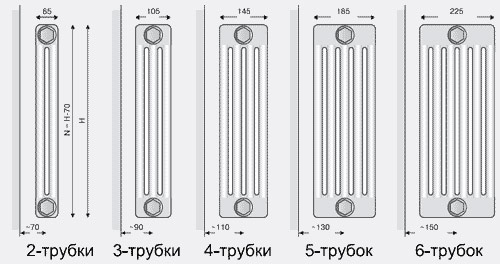

Welded steel pipes make up the core of this heater. However, it also serves as a corps. To make such a radiator is not as simple as the previous one, but it undoubtedly has much more variations of models. The most common classic option is a radiator similar to a cast-iron, but having much more channels for the movement of the coolant.

The number of channels that a pipe radiator can have.

Such a device is quite expensive, and it can not be called a budget option. It is rather an option for the designer, not constrained by the means.

All possible colors of pipe radiators.

His imagination, coupled with vibrant colors, original shapes and the entire range of sizes, makes these radiators a real highlight of the stylish and beautiful interior.

And about the price: any bimetallic radiator of a well-known European brand is cheaper than a tubular one, even made in Russia.

The most important characteristics of steel radiators

Heat dissipation

With heat transfer, things are not bad at all - the heat transfer rate varies from 1200 to 1800 watts and even more. This parameter depends on the dimensions of the radiator, its brand and type of specific model. Note that the big advantage of these devices is the low inertia. They heat up very quickly and begin to give off heat to the room.

The process of heat transfer from them occurs in two ways - this is direct heat radiation and heat transfer by convection.

Operating pressure

The maximum working pressure for this type of radiator ranges from 6 to 10 atmospheres for plate radiators. This parameter is limited due to a steel property such as ductility. However, tubular radiators can withstand greater pressure - from 8 to 15 atmospheres. All this means that steel radiators cannot be used in central heating systems. They will not be able to withstand the pressure of the central heating system.

Coolant quality

An important detail is how “gentle” the radiator will be in relation to the quality of the coolant. For steel, this is a real stumbling block - because it rusts so easily when air comes into contact with water. However, manufacturers do not give up - they are trying to overcome this problem. Apply special internal coatings for protection. But, unfortunately, this struggle often ends with the victory of corrosion. Therefore, it is better not to install steel radiators in an apartment of a multi-storey building. In summer, water will be drained, and rust will begin to eat radiators.

Coolant temperature

The maximum temperature of hot water that steel batteries can withstand is from 110 to 120 degrees.

Center distance

Steel radiators can have both side and bottom connection. The center distance is important for radiators with a lateral connection. It determines how far the upper collector is from the lower. This must be taken into account when installing the radiator. Depending on the model, type and manufacturer, steel panel radiators can have a center distance equal to the radiator height minus 50 - 70 cm. For tubular steel radiators, the center distance varies between 120 mm and 2930 mm.

dimensions

Now a few words can be said about external parameters, in particular, about dimensions. The length of the panel-type radiators can reach 3 meters, their height - from 20 to 90 centimeters. A tubular radiator can be made of almost any length, and its depth is limited by the size of 22.5 centimeters. Height varies from 19 to 300 centimeters.

Steel thickness.

Few people pay attention to this indicator, however, manufacturers for the manufacture of steel radiators use steel of various thicknesses. This indicator can vary from 1.15 to 1.25 mm. It is clear that the thicker the steel the better.

Durability

Thanks to the material of manufacture - strong and reliable steel - these radiators are able to live a long life without letting their owners down. Especially good are high-quality products with thick walls (0.12-0.15 cm) produced by reliable and responsible brands.

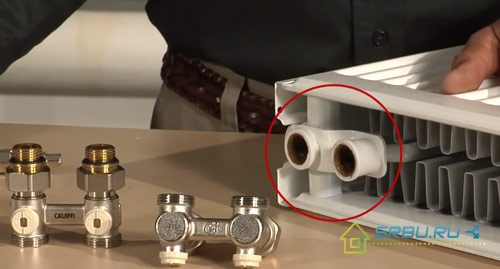

Ease of installation

Installation of these heating devices is not very complicated. Moreover, it is very convenient that it is possible to choose a panel-type radiator with a connection both from the side and from the bottom. In the latter case, the pipes can also be hidden under the floor, and the temperature sensor is connected directly to the radiator. And the panels of the radiator itself can be connected in series or in parallel - both types of models can be found on sale.

Panel type radiator with bottom connection system.

Cons and pros of steel heating radiators

First about the virtues

- They have good heat transfer, which occurs not only by heating the air, but also in the case of panel-type radiators by convection.

- Since the design of these radiators is not difficult, then there’s nothing special to break into them. Due to this, their service life is quite long.

- These radiators are lightweight, so they are convenient to mount. Moreover, there are always several installation options - models with a variety of connections are available.

- Steel radiators are cheaper than similar aluminum models.

- The appearance of steel radiators is very attractive, so they can even become an interior decoration.

Now about the shortcomings

- The biggest drawback is the inability to resist corrosion. As soon as the water stops flowing through the steel battery, it immediately begins to rust. Therefore, these radiators are absolutely not suitable for central heating systems, where as a rule, water is drained for the summer period for maintenance and repair.

- Having studied the characteristics of steel heating radiators, we see that they cannot withstand water hammer. After all, they have welded parts, the seams of which also can not withstand increased pressing pressure. The radiator can then lose shape, or even burst at the seams. Therefore, steel radiators can only be used in autonomous heating systems and a point.

- Unfortunately, sometimes paint on a steel radiator of not very high quality does not hold well. Therefore, after several heating seasons, peeling of the coating occurs.

Steel radiator manufacturers

Panel Type Radiators

In Russia, such radiators are practically not available - foreign-made products are very favorable to the buyer. Manufacturers from Germany - Buderus and Kermi, from the Czech Republic - Korado, from Finland - PURMO, from Italy - DeLonghi can be noted. Each company has in its entire arsenal radiators that differ in height, length, depth, and, accordingly, power. Therefore, these data must be viewed directly in the passport of a specific radiator model. There are a huge number of models and it is very problematic to present all their technical characteristics within the framework of this material. Therefore, for comparison, we take a radiator type 22 (has 2 panels and 2 convector fins), the size of 500/500 mm of some manufacturers.

Comparative characteristics of radiators of type 22, 500 mm wide, 500 mm long, by popular manufacturers:

| Manufacturers | Working pressure, atm | Max. t coolant 0FROM | Power at 70 0C, W | Water volume | Weight | Connection method |

|---|---|---|---|---|---|---|

| Kermi Germany |

10 | 110 | 965 | 2,7 | 17,07 | Lateral - a carving 4 x 1/2 "(vnutr.) Lower - 2 x 3/4 ”thread (out.) |

| Buderus Germany |

10 | 120 | 913 | 3.15 | 14.1 | Side Lower, with integrated thermostat valve |

| Lidea Belarus |

8,6 | 110 | 1080 | 3,3 | 15,1 | Lateral - 4 connecting branch pipes with a female thread 1/2 " Lower - 2 connecting branch pipes with a female thread 1/2 " |

| KORADO Radik Czech |

10 | 110 | 914 | 2 | 15,6 | Lateral - a carving 4 x 1/2 "(vnutr.) Lower - 2 x 3/4 ”thread (out.) |

| Purmo Finland |

10 | 110 | 929 | 2.6 | 13.6 | Lateral - a female thread 1/2 " Lower - internal thread 2 x 1/2 " |

| DeLonghi RADEL Italy |

8.7 | 110 | 1079 | 3.1 | 14.9 | Lateral - thread 4x1 / 2 " Lower - 2 x 1/2 " |

* All data is taken from official sources of manufacturers

Tube type radiators

These more expensive products are produced by fewer companies. Perhaps most of them in Germany are Zehnder Charleston, Arbonia, Kermi, Charleston. In Italy, such batteries are made by Israp Tesi. In the city of Kimry, Tver Region, there is a KZTO plant that produces radiators with a working pressure of up to 15 atmospheres. They can even be suitable for an apartment in a multi-storey building, withstanding the pressure instability in central heating.

Video: Production of steel panel radiators